PVcase Prospect

Automate site selection and analysis with comprehensive integrated data for smarter decisions.

The solar photovoltaic industry continuously seeks ways to enhance efficiency and reduce costs. DC wiring, while fundamental, has traditionally been a significant source of both expense and complexity in ground-mounted solar projects due to manual, on-site methods. ENGESOLAR, a leading cable assembly solutions provider, has addressed this by leveraging PVcase software. Recognizing a market need where pre-assembled wire harnesses are standard, and driven by project developers seeking cost-effective pre-assembly solutions, ENGESOLAR set out to become a 360-degree DC wiring solution provider in the German and European markets.

Traditional DC wiring in ground-mounted solar plants, which involves connecting individual PV strings with separate cables, presented several critical challenges for ENGESOLAR and their clients:

Calculating string lengths from PDF files for project quotes was a manual, hours-long bottleneck.

The manual nature of this process increased the likelihood of mistakes such as incorrect cable lengths, improper connections, and inconsistent quality control.

As a new entrant into solar design, ENGESOLAR needed a robust and intuitive tool to efficiently plan ground-mounted parks.

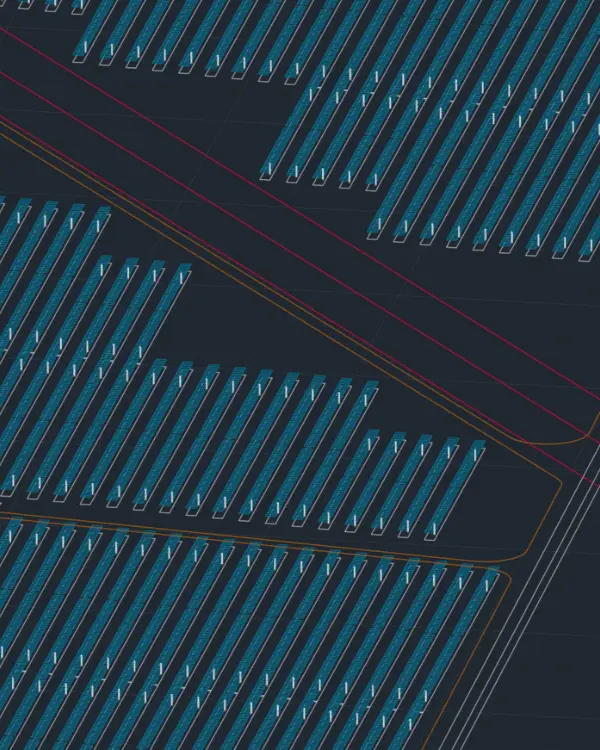

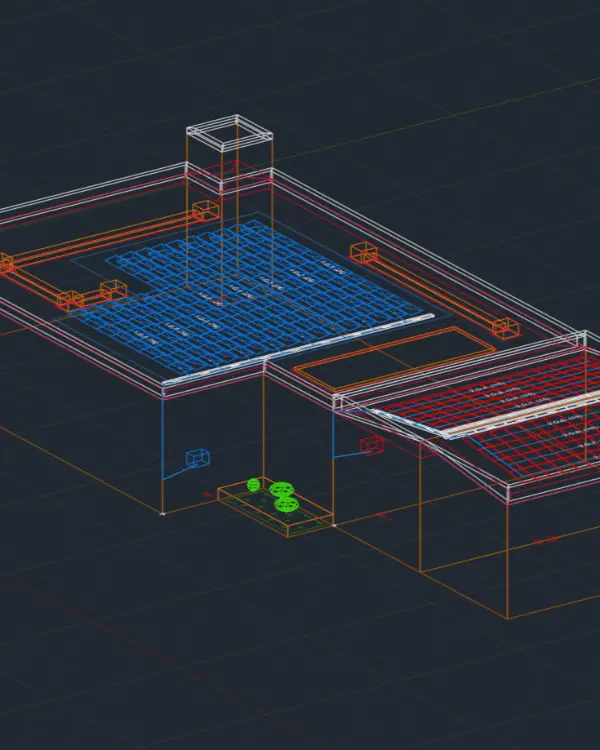

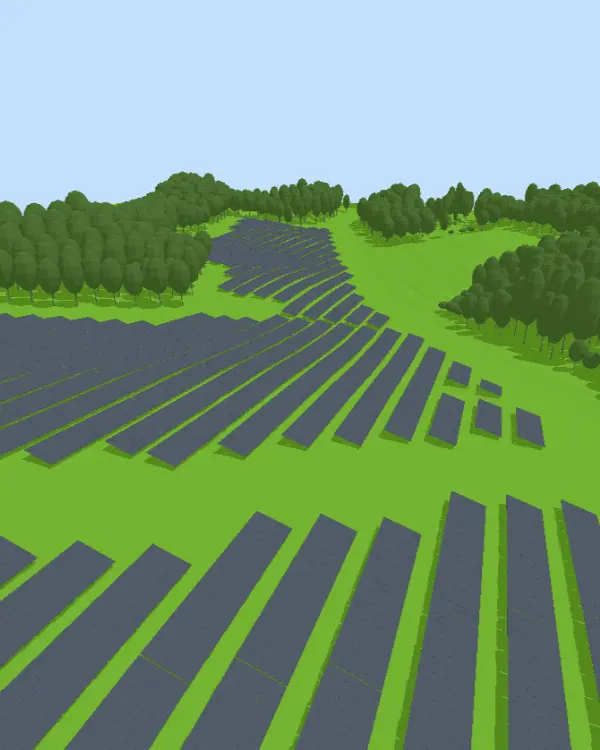

ENGESOLAR adopted PVcase Ground Mount as the cornerstone of their strategy to address these challenges and establish themselves as a comprehensive DC wiring solution provider. PVcase Ground Mount became a crucial tool for automating and optimizing the design process for DC string harnesses. This innovative feature, Harness Manager, directly tackles the shortcomings of previous, less realistic harness functionalities, often resulting in designs that failed to account for practical installation scenarios. With Harness Manager, ENGESOLAR incorporates detailed cable harnesses into its ground-mounted PV designs with unparalleled accuracy and efficiency. Ready to see how Harness Manager can transform your DC wiring designs? Learn more.

ENGESOLAR, a brand of the Engeser Group, is a leading global provider of specialized cable assembly solutions. With a focus on innovation and quality, Engesolar recognized the need to optimize DC wiring processes within the solar photovoltaic industry. Their expertise in cable manufacturing, combined with strategic technology adoption like PVcase, enables them to deliver cutting-edge, pre-assembled DC string harnesses.

Automate site selection and analysis with comprehensive integrated data for smarter decisions.

AutoCAD-driven software for faster, more accurate utility-scale solar design.

Maximize C&I rooftop solar design efficiency with advanced AutoCAD-driven software.

Precise and efficient energy modeling for optimal solar project performance.

Turn complexity into clarity and confidently move your solar project forward.