Precision in solar simulations: PVcase Yield and PVsyst loss calculations

For solar professionals, accurate energy yield predictions are the bedrock of successful project development. Tools like PVsyst have long been the industry standard, but with the rise of advanced 3D modeling and ray-tracing capabilities, software like PVcase Yield is setting new benchmarks for precision. While both serve the critical function of simulating energy production, they approach the task with different methodologies and levels of detail in certain areas.

This blog post is your guide to understanding the nuances of how PVcase Yield and PVsyst handle various loss mechanisms. To help you choose the best solution for your needs, we have prepared a comprehensive, downloadable PDF — PVcase Yield vs PVsyst comparison. Download your copy today and get the clarity you need to make the right choice.

Table of Contents

- 1. Understanding the core inputs and data handling

- 2. Understanding the core inputs and data handling

- 3. Deconstructing loss mechanisms: different approaches

- 4. Deconstructing loss mechanisms: different approaches

- 5. Deconstructing loss mechanisms: different approaches

- 6. Analyzing output metrics and reporting philosophies

- 7. PVcase Yield vs PVsyst comparison guide

1. Understanding the core inputs and data handling

The foundation of any simulation lies in its models, and any simulation is only as accurate as its inputs. Before diving into output comparisons, ensure that the fundamental parameters are as consistent as possible between PVcase Yield and PVsyst. However, it's crucial to understand how each solution process or interpret this data.

Geographical data & meteorological data

PVcase Yield is tightly integrated with the 3D design environment, leveraging the detailed site model to conduct high-fidelity PoA irradiance calculations based on precise module placement data and a comprehensive sky radiance distribution model. It also supports direct integration with PVGIS and SolarAnywhere, while enabling users to manually upload custom climate files from other sources.

PVsyst integrates with various climate data sources (such as PVGIS, Meteonorm, SolarAnywhere, and Solargis), and also enables users to import and process their own weather data from meteorological stations. A simulation requires the selection of a weather file that defines hourly values for global horizontal irradiance (GHI), direct normal irradiance (DNI), diffuse horizontal irradiance (DHI), temperature, and wind speed. PVsyst's then uses a transposition model to calculate plane-of-array (PoA) irradiance.

Key comparison point: verify the source and consistency of the weather data. Even if both use a "TMY3" file, ensure it's the same TMY3 for the exact same location. Pay attention to how each tool derives PoA irradiance, especially in complex terrains or layouts, as PVcase's 3D model allows for very precise geometric calculations.

.png/10f52ecca79c5d5c84177c63c9bee761/image-(25).webp)

Module and inverter specifications

Over the years, the PV industry has adopted PVsyst file formats for describing PV modules (.pan files) and inverters (.ond files) technical specifications. PVcase Yield has also adopted this standard and allows users to upload the same files they used to use in PVsyst.

Key comparison point: while seemingly straightforward, ensure the exact same .pan and .ond files for the same models and manufacturers are selected. Subtle differences in temperature coefficients, IAM (incidence angle modifier) profiles, or inverter efficiency curves (e.g., partial load efficiencies) can lead to variations. Check if one solution uses a simplified model versus a more detailed one for a specific component.

System sizing and configuration

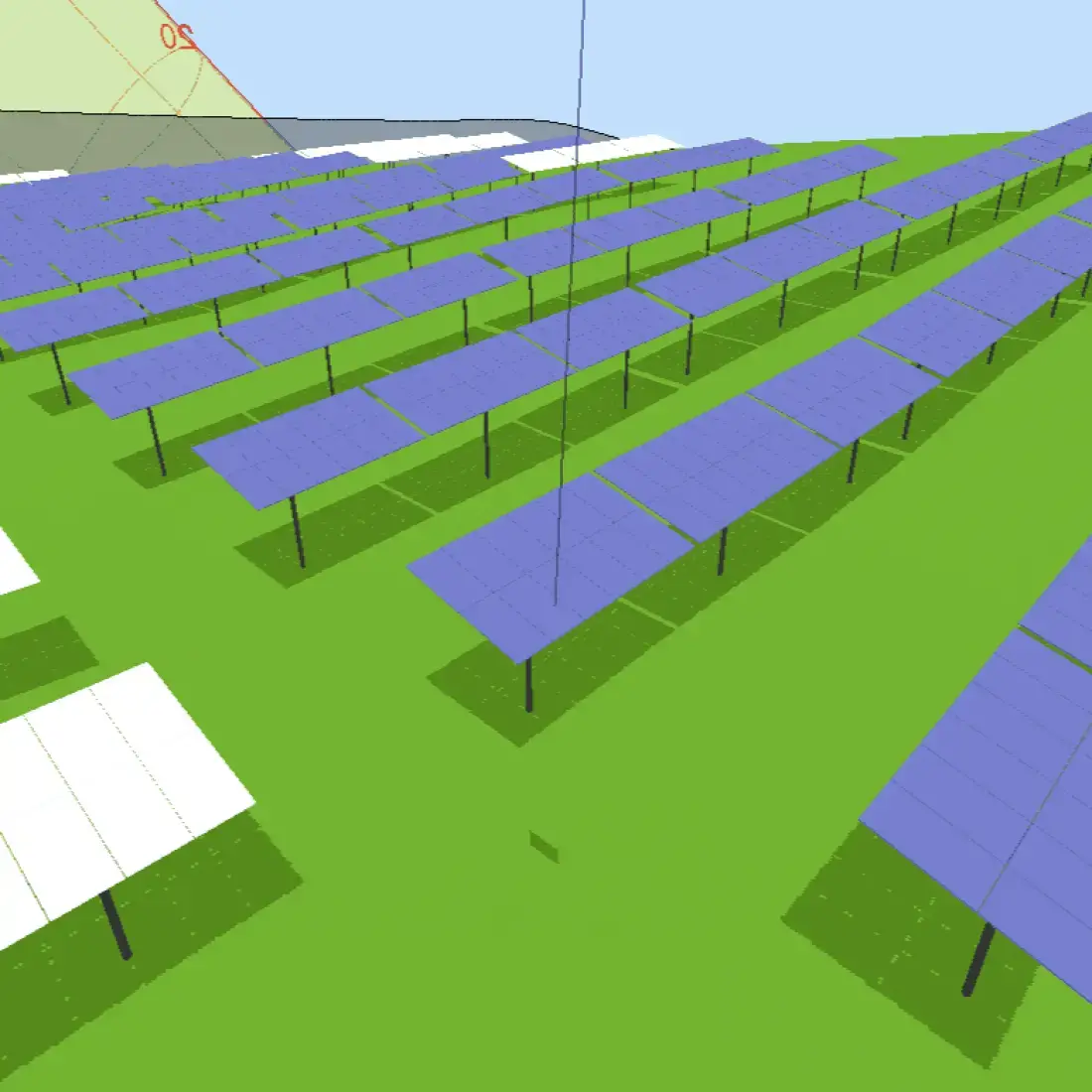

PVcase Yield excels in the physical, spatial design. Its strength is in precisely placing modules in 3D space, defining row spacing, tilt angles, and stringing within a visually accurate environment. This directly feeds into its shading calculations.

PVsyst is more focused on enabling users to define the system architecture without requiring a detailed PV layout or design. While it has 3D modeling capabilities, its initial setup often begins with defining the number of modules, strings, and inverters, then placing them within its simulation environment.

Key comparison point: ensure the total installed DC capacity, modules per string, and strings per inverter are identical. Most importantly, carefully compare the physical layout parameters such as inter-row spacing, ground coverage ratio (GCR), and tilt/azimuth angles. PVcase's exact 3D representation will directly inform its calculations of these parameters.

2. Deconstructing loss mechanisms: different approaches

Both PVcase and PVsyst account for various loss mechanisms, but their underlying calculation methodologies and the granularity of their models can differ significantly. This is often the primary source of discrepancies in the final energy yield.

PVsyst vs PVcase shading loss

PVcase Yield's core strength and advantage lie in its precise and robust 3D modeling capabilities. Shading calculations in PVcase Yield are typically based on a highly accurate ray-tracing approach derived directly from the detailed 3D site layout. Furthermore, it employs the same method to calculate irradiance and shading on both the front and back sides of the PV modules. This allows for very granular analysis of self-shading, near shading from obstructions (buildings, terrain), and far shading (mountains, horizon).

PVsyst: offers 3D shading analysis. It builds a 3D scene from defined objects (rows, fences, trees, terrain). PVsyst's approach calculates hourly shading factors for each module or array, often using a combination of geometrical calculations and numerical integration over the sun's path. However, the back-side irradiance and shading calculations are considerably more simplified compared to the front side and rely on a greater number of assumptions. It can model both irradiance and electrical shading (mismatch) losses and electrical shading losses.

Key comparison point: this is a critical area. PVcase's detailed 3D output for a specific design might show more precise or localized shading effects. In particular, back-side irradiance calculations may show notable differences, given that the PVsyst method is based on numerous assumptions. Ensure both tools are set up to capture the same shading objects and methodologies (e.g., if one is set to ignore certain far shading while the other includes it). Pay attention to how electrical mismatches due to shading are modeled, as PVsyst provides multiple approaches with different levels of detail to address this.

.png/0cb8c116089dab1eec60d10c68c83150/image-(27).webp)

Temperature losses

PVcase Yield: its integration with the physical design might implicitly influence how module temperatures are distributed across the array, especially if there are ventilation differences due to mounting structures.

PVsyst: estimates the module temperature using an energy balance model with two empirically derived heat loss coefficients. This approach allows users to fine-tune the thermal model when module temperature measurements from the PV plant are available.

Both solutions: rely on the single diode model to calculate thermal losses, using parameters such as the thermal coefficients that are specified in the .pan file.

Key comparison point: ensure that the thermal coefficients in the .pan files are consistent and that the empirical heat loss coefficients are appropriately selected.

Mismatch and wiring losses

PVcase Yield: can incorporate stringing and cable length details from the plant’s electrical design to accurately model wiring and electrical mismatch losses. However, if only a mechanical layout is available, it relies on user-defined estimates to estimate mismatch losses.

PVsyst: offers detailed models for DC wiring losses based on wire lengths and gauges, and a range of models with varying levels of complexity and accuracy to account for electrical mismatch within strings and between strings due to manufacturing tolerances, partial shading, or degradation.

Key comparison point: ensure comparable percentages or calculation methods for these electrical losses. If PVsyst models mismatch in more detail, try to map that to a general percentage or set of assumptions in PVcase, or understand why PVsyst calculates a higher value.

.png/2169f503a68903a7f9a79bcc3aa05cbd/image-(26).webp)

Inverter losses

PVcase Yield: provides detailed modeling of clipping, derating, and conversion efficiency. Badly sized inverters can be detected through high inverter losses using Yield's intuitive loss diagram.

PVsyst: provides detailed modeling of the inverter’s voltage window, current limiting, and clipping. It assists users with inverter sizing and offers a comprehensive breakdown of inverter-related losses.

Both solutions: use inverter efficiency curves from the .ond file.

Key comparison point: ensure that the specifications in the .ond files are consistent and that the inverter sizing in PVcase Yield is appropriate.

3. Analyzing output metrics and reporting philosophies

Beyond the total annual energy yield (kWh/year), compare other key performance indicators that can shed light on the simulation differences. The way each solution reports these can also vary.

Performance Ratio (PR): both solutions calculate Performance Ratio (PR), but the components included in the calculation may differ slightly depending on how losses are categorized. Additionally, for bifacial systems, PR values may vary between tools, as the calculation methodology for this metric is not yet clearly defined in the IEC standards.

Specific Yield (kWh/kWp): a common metric for both.

Monthly/Hourly production: both provide hourly time-series simulations and annual energy summaries.

PVsyst: offers more detailed monthly breakdowns and includes additional intermediate calculations within its hourly data.

PVcase Yield: reports the spatial performance distribution due to its 3D modeling capabilities.

Loss Diagrams/Tables: both solutions provide a breakdown of losses, but their categories and the order of calculation might differ. Carefully map each loss category from one tool to the other to understand where divergences occur. For example, PVsyst may report the "Incidence Angle Modifier" only for the front side of the modules, whereas PVcase Yield might provide it for both the front and rear sides.

Interpreting loss percentages: a crucial point to remember when comparing loss figures, especially those expressed as percentages, is their reference point. The same absolute loss in MWh might appear as different percentages if the baseline (e.g., plane-of-array irradiance vs. DC nominal power) differs between the tools. In scenarios where percentage-based comparisons become ambiguous due to varying baselines, it can be more insightful to directly compare losses in absolute units, such as MWh, to get a true picture of their impact on the final energy yield.

PVcase Yield vs PVsyst comparison guide

Ultimately, the key to comparing simulation results between PVcase Yield and PVsyst isn't just about finding the exact same number, but about understanding the journey of how that number was reached. As this analysis shows, while both solutions excel in their respective domains, the nuances in their methodologies can lead to meaningful differences.

PVcase Yield’s 3D-first approach, particularly in complex shading calculations and spatial performance reporting, provides a detailed, granular view that is invaluable for projects where site specifics directly influence yield. By leveraging the same inputs and meticulously comparing the outputs, engineers can reconcile differences and build confidence in their modeling. In an industry where project accuracy is paramount, knowing which tool is best suited for your specific needs — and why — is the ultimate advantage.

Download the PVcase Yield vs PVsyst comparison guide and choose the best solution for accurate solar project energy prediction.

Book a personal demo

Find out how to get precise yield projections for any PV technology or site, eliminating manual workarounds and guesswork at every project stage.