The future of advanced materials

Advanced materials are engineered substances that offer superior properties or novel functionalities compared to conventional materials. The specific needs and qualities of these materials can vary by industry. For instance, materials that meet performance requirements in industries such as aerospace, healthcare, and agriculture will likely have very different properties due to the nature of the industries.

Composite materials like carbon fiber offer a combination of light weight and strength that helps improve fuel efficiency in flight-related applications. However, these capabilities are less likely to be important in healthcare. Advanced biocompatible materials help medical implants integrate more smoothly within the human body but have less application in agriculture. Advanced polymers that help improve soil quality or minimize pesticide use would be irrelevant to both aerospace and healthcare.

Although the practical applications and possibilities presented by advanced materials differ between industries, they still represent a promising area of development for similar reasons. Let's explore the future of advanced materials in this article.

Trends driving the future of advanced materials

As businesses and organizations strive to find replacements for heavy and expensive materials like metal, the need for lightweight, sustainable alternatives grows. With the potential to provide benefits like a greater strength-to-weight ratio and increased durability, these materials have the potential to reduce carbon emissions in production as well as in their ultimate utilization.

Advancements in manufacturing technology can also help drive these innovations, as more sophisticated materials can be made through cost-effective processes like 3D printing and additive manufacturing. In turn, these new materials can help to enable other technologies like more efficient batteries. For example, the Office of Energy Efficiency and Renewable Energy’s Advanced Battery Materials Research Program aims to develop advanced materials for applications like electric vehicle batteries.

In addition to the materials themselves, the production processes can be improved to better facilitate their use at scale.

Innovations in production processes

Emerging technologies can play a role in developing advanced materials, making the process more cost-effective and environmentally friendly. The following techniques and technologies can help with production, reducing the need for costly labor and enabling complex creations that would otherwise be impractical.

3D printing

3D printing allows the production of complex structures with minimal materials. Since a structure can be designed to exact specifications and created directly from digital blueprints, 3D printing presents opportunities to create specialized structures that meet specific needs.

Structures can be 3D printed from a variety of materials, including plastics, resins, and metals. This gives the technology versatility in providing a structure that perfectly matches the designer’s needs. It also highlights the potential for more advanced materials to be 3D printed, giving the technology even more applications.

Artificial intelligence

Artificial intelligence (AI) can help identify ways to optimize manufacturing processes, reducing energy consumption and waste. AI-powered systems can also detect defects in real-time, improving yield and reducing material waste.

AI can examine large datasets to identify bottlenecks in materials production, potentially making processes more efficient and reducing costs. This is particularly important as new materials are developed and used to track and better understand potential issues with their production.

Biomanufacturing

Advanced materials play a crucial role in innovating production processes in biomanufacturing. For example, bioreactors can be improved through the use of corrosion-resistant alloys that can help improve durability or reduce risks of contamination.

Businesses can also use biological systems to create advanced materials through genetic engineering. This can be used to create more biocompatible materials that can also be biodegradable and have less of an environmental impact.

Solar-powered production

Solar energy can reduce the carbon emissions typically associated with advanced material production, amplifying the sustainability of these materials through green energy use during production.

Combined with automation, solar-powered production has the potential to make material production nearly autonomous, reducing labor costs and carbon emissions.

Potential impact on industries

The development of advanced materials can profoundly impact various industries, improving efficiency, reducing costs, and creating new opportunities. Some industries that stand to benefit include aerospace and defense, healthcare, farming, and renewable energy.

Aerospace and defense

Composite materials are lightweight and strong, and they can help improve aircraft efficiency by reducing weight without compromising durability. This can reduce fuel consumption, making flights more cost-effective. That can save money in air travel and industries that use drone technology. These materials can offer corrosion or high-temperature resistance, increasing their utility in adverse environments.

Healthcare

Advanced materials allow for more biocompatible medical devices and implants. They even allow for more sophisticated technology to support these devices. For example, energy harvesters within the body can help power biomedical devices and dissolve naturally when no longer needed. This gives doctors and healthcare professionals more options for monitoring a patient’s health or administering treatments.

Nanostructured surfaces can offer self-disinfecting properties that help reduce the spread of infections or other contaminants in healthcare facilities.

Farming

The integration of advanced materials in agriculture has the potential to significantly improve sustainability, productivity, and efficiency. This can help with the sustainable cultivation of climate-resilient crops. For precision agriculture, these materials enable more accurate monitoring and targeted treatments.

As research progresses and costs decrease, wider adoption of these materials may occur, which could contribute to a more sustainable and productive agricultural sector. Farms implementing these technologies can demonstrate their use in educational exhibits, helping to promote their utility.

Renewable energy

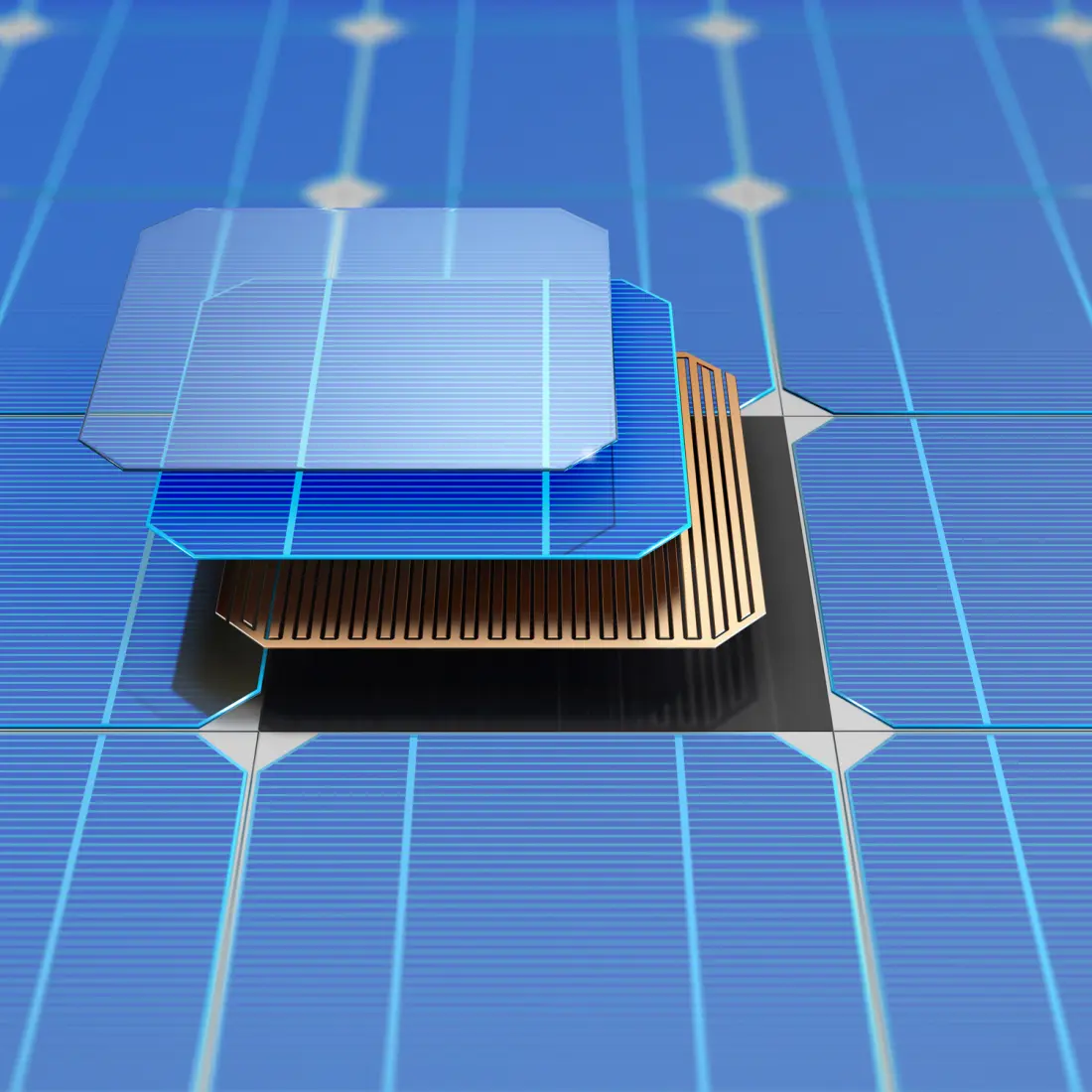

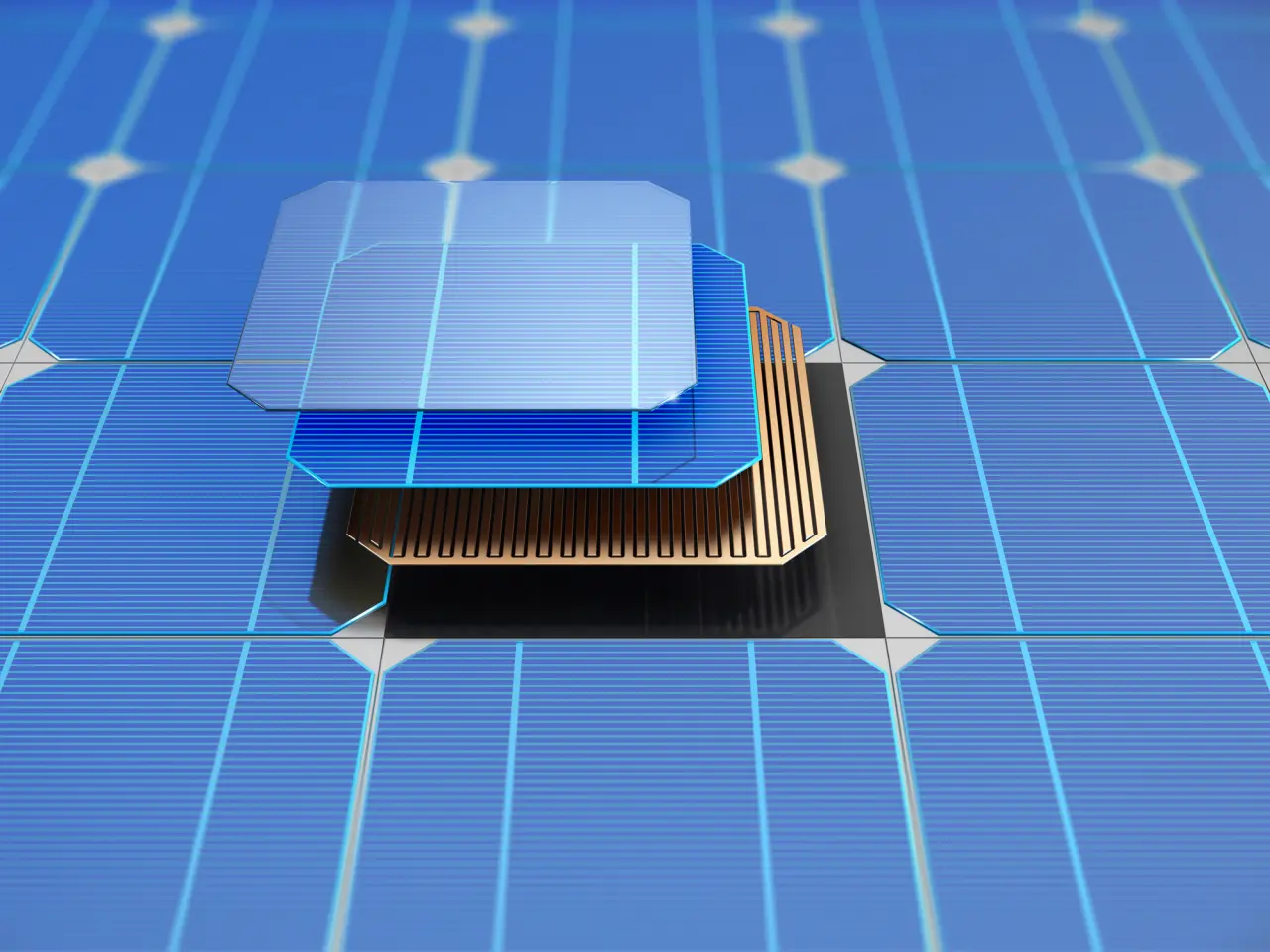

Advanced material development can help increase the effectiveness of renewable energy efforts. For example, improved photovoltaic materials can allow the potential for higher-efficiency solar panels with lower production costs.

Advanced concrete and steel formulations can result in more durable structures, which can be helpful for wind turbine foundations and towers. Concrete 3D printing can even help expand the versatility of foundations with more control over a concrete structure.

Opportunities for businesses

Regardless of industry, using advanced materials can also help businesses surpass their competition. The opportunities presented for innovation and cost-effectiveness allow businesses to provide better service to customers and enhance profitability.

Customization

Through the use of 3D printing and AI, businesses can offer more specialized products and services. They can create prototypes and even finished products that cater directly to a customer’s needs without relying on pre-existing products or making costly updates to manufacturing processes.

Customization can reduce waste and cost through more efficient material use. This can help enhance products being offered to customers, providing a better value while remaining competitive.

Cost savings

Advanced materials have the potential to reduce waste and energy consumption, which can lead to cost savings both in production and application. For uses like drones and other aerial devices, lighter-weight materials can help to reduce the energy expended to remain in the air. More durable materials may also reduce the need for costly maintenance.

Though the initial investments can sometimes be higher, the long-term cost savings can potentially outweigh upfront costs. Businesses must conduct thorough cost-benefit analyses to determine the most appropriate advanced materials for their needs.

Sustainability

Participating in green initiatives and sustainable practices can help demonstrate a company’s mindfulness and care for the environment, which can attract attention from similarly environmentally conscious consumers.

Conclusion

Ultimately, advanced materials have the potential to offer properties that make old applications better and new applications possible. Healthcare, aerospace and agriculture are only a few examples of industries that stand to benefit, but the possibilities for improvement are present across all industries.