The role of automated solar design software in solar project development

The solar industry is a demanding one. Efficiency directly equates to profitability, so design and implementation speed are more critical than ever.

However, solar designers can shorten solar project timelines from what used to take hours to minutes. This isn’t just a daydream, but a bold fact as automated solar design software became widely available.

Traditionally, solar project design involved a labor-intensive process with endless revisions and manual adjustments. Engineers and designers worked meticulously through each stage, often double-checking and recalibrating their work to ensure accuracy. This painstaking attention to detail, while necessary, slowed down projects and increased costs. The frustration of seeing a project's timeline extend further than anticipated is an issue many solar professionals know all too well.

That’s where automated design steps in. The tool is rapidly reshaping the landscape, offering a streamlined approach that promises the best of both worlds — precision and speed. Moreover, automated design is valuable for minimizing the risk of human error, ensuring higher reliability and efficiency.

Continue reading this article and learn about the game-changing role of automated solar design software, how it's turning the long-established solar workflow on its head, and how PVcase transforms the traditional solar project process from hours (or even days) to mere minutes.

Efficiency challenge in solar projects

Efficiently managing solar projects involves navigating key challenges like the time-consuming design process and manual work's impact on accuracy. Frequent revisions extend timelines, and using separate tools for each stage of a solar project causes errors. Let’s explore the main challenges.

1. The time-consuming nature of solar project design

Traditionally, the solar design process is lengthy, primarily due to the need for constant revisions. Initial designs may not take much time, but changing or optimizing these designs often extends timelines, especially when solar designers must modify the project closer to, or during, construction.

This delay creates a ripple effect, as other teams or equipment on-site may have to wait for the updated design before they can proceed. The compounded time loss from repeated design updates ultimately impacts overall project efficiency and profitability.

2. Implications of manual work on project accuracy

Manual tasks, while mostly phased out, still play a role when developers use disparate tools for different stages (e.g., shading analysis, layout configuration, system sizing, yield estimation). This lack of integration across tools can introduce errors or inefficiencies due to data being transferred multiple times. Unfortunately, frequent data transfers between different tools further increase the risk of errors, loss of detail, and time delays.

How does automated solar design software solve efficiency challenges?

The most effective method for tackling efficiency challenges like lengthy processes and inaccuracies is to integrate multiple functions within a single workflow. This allows solar designers to reduce development time, minimize rounds of revisions and adjustments, and avoid data risk challenges that come with using different tools for various project stages.

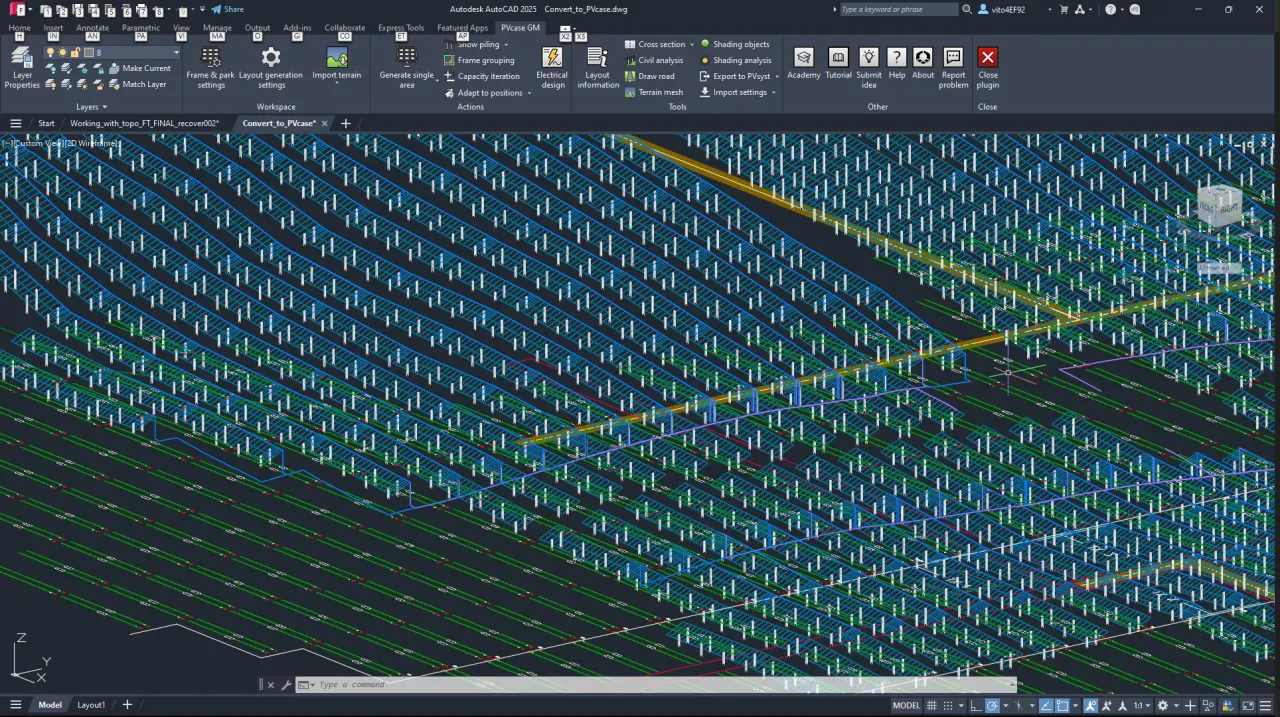

PVcase's automated solar design platform, including PVcase Prospect for site selection and PVcase Ground Mount for layout configuration, streamlines workflows by reducing time and minimizing errors by eliminating the need for data transfers between applications. With accurate and realistic design outputs early on, these solutions quickly assess site buildability and optimize layouts, effectively addressing efficiency challenges in solar projects. Let's look closer at how PVcase's solutions address efficiency challenges.

1. Streamlined design processes

To begin with, automated solar design software such as PVcase Prospect and PVcase Ground Mount allow solar designers to handle site analysis, system sizing, and layout setup all in one place. Data transfer between PVcase Prospect and PVcase Ground Mount takes mere seconds. This seamless integration minimizes data loss and setup time, streamlining each development phase.

After identifying buildable areas in PVcase Prospect, the entire project can be handed over from the Project Developer to the Project Engineer, who can then pick up the detailed engineering work in PVcase Ground Mount.

“PVcase has transformed our process, allowing us to move from manual drawings to a more automated, precise system. This change has streamlined our workflow significantly.” Mário Gonçalves, CAD Design Team Coordinator at Voltalia

What's better? Each platform offers a bundle of features that help design faster, better, cheaper, and more efficiently. One of the functions that significantly contribute to the reduction of time and errors is the PVcase Ground Mount’s Capacity Iteration, a tool that Project Engineers use to try multiple configurations quickly and select the best design. Users can change variables such as row pitch, ground coverage ratio, and other parameters to test different layout scenarios and compare energy outputs in PVcase Yield. This level of customization, combined with automation, enables solar designers to find the most optimal designs in just a fraction of the time.

Hence, the easy integration of PVcase Prospect and Ground Mount, and a fleet of notable automation features, significantly rationalizes the overall design process. This array of benefits allows users to bypass lengthy design phases and reduce the impact of manual work on accuracy, efficiency, and effectiveness for solar designers.

2. Reduced data risk and human error

Using a single platform for multiple design stages reduces the risk of human error associated with manual data entry and data transfers across different tools. With PVcase, data is entered once, eliminating redundant entries and minimizing the chances of error at every project stage.

For example, PVcase Prospect provides accurate and reliable terrain data, with which PVcase Ground Mount users can perform real-time shading analysis, layout configurations, and other critical tasks in one environment. Having this data available in such high resolution and at such an early stage of the project ensures a high design quality for the rest of the Project lifecycle.

In addition, PVcase Yield calculates the project output with accurate 3D ray tracing even before building, further decreasing the likelihood of oversight or error and ensuring that designs are accurate and consistent.

In short, PVcase does the job for you, thanks to automated design tools and software compatibility, ensuring that each project stage is in sync with accurate data.

3. Accelerated project timelines

The automation capabilities of our solar software allow solar developers to complete various project stages more quickly. Users can transition between PVcase Prospect, PVcase Ground Mount, and PVcase Yield for project estimation within minutes, allowing for a full-fidelity model from the start. This early-stage accuracy ensures that preliminary designs are reliable, reducing the risk of delays due to inaccurate or incomplete data.

For example, PVcase Prospect allows users to generate highly accurate designs based on high-quality digital elevation models to process slope. This eliminates the need for developers to create rough estimates, as they can rely on PVcase’s high-precision terrain data from the beginning.

Automation accelerates timelines by enabling real-time feedback and faster iterations. For instance, using PVcase, developers can complete the full design process in under an hour. Critically, making changes to the design is also lightning-fast. So, the design does not hold everything up at those crucial moments in the project's construction. This time-saving aspect and better accuracy make automated design valuable for solar developers who need quick, reliable project outcomes.

Key components of automated design software in solar projects

Automated design software streamlines the typically time-consuming processes of site selection, design, and yield estimation, enabling companies to become faster, more efficient, and more profitable. But what are the essential components of transformative automated design software, such as PVcase Ground Mount? Here's a quick overview:

1️⃣ High-accuracy terrain data: PVcase Prospect provides accurate lidar data with a five-centimeter resolution for precise topographical mapping. PVcase Ground Mount incorporates global terrain data from online sources, providing terrain for any location on Earth so developers get the most accurate foundation for their designs.

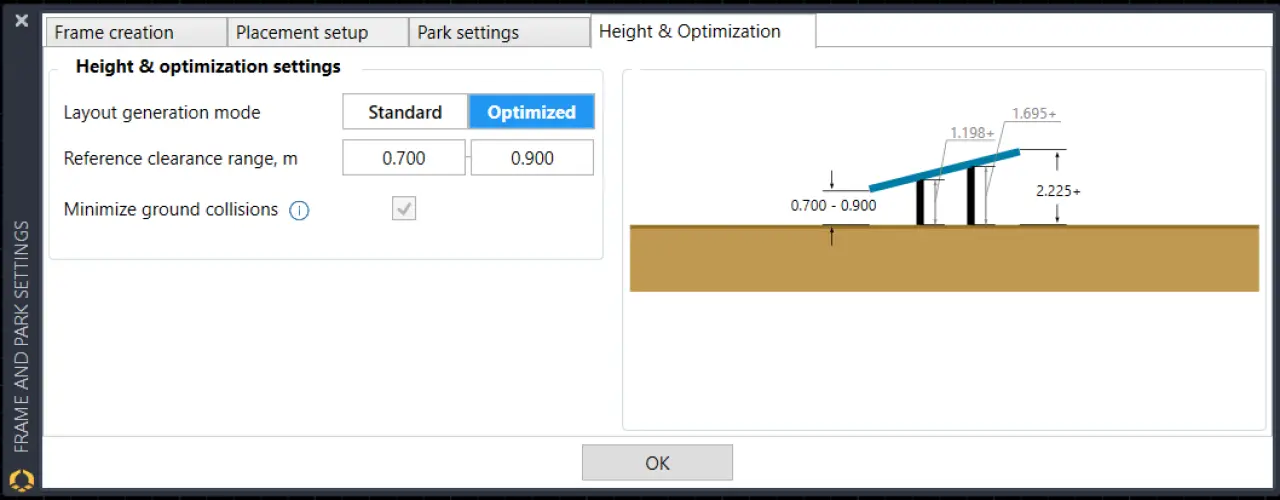

2️⃣ Automated layout optimization: PVcase Ground Mount uses advanced algorithms to optimize panel placement, maximizing energy output. Its capability to adjust for Terrain-Following Trackers allows solar companies to position panels effectively, thus reducing both energy and material costs.

3️⃣ Data-driven performance simulations: with PVcase Yield, users can conduct detailed energy yield simulations to assess potential performance based on layout configurations. This feature can perform yield analysis early in the project, guiding users to select the best layout for maximum energy output.

4️⃣ Interoperability with other software: PVcase’s export capabilities facilitate seamless data transfer, including ground grading exports compatible with AutoCAD Civil 3D. These integrations ensure a smooth and cohesive transition from design to construction, enhancing the overall project workflow.

Benefits of adopting automated design software

Solar companies get scaling opportunities by opting for automated solar design software that not only streamlines the design processes but also reduces the likelihood of human error.

Crucially, easy adjustments, regardless of the project phase, and seamless compatibility of PVcase Prospect, PVcase Ground Mount, and PVcase Yield help users prevent costly delays, even when on-site teams are ready to construct. Here's an overview of the benefits you get by adopting automated design software.

1. Increased efficiency and speed

Automation tools allow solar companies to explore multiple design options quickly, ultimately expediting project timelines and reducing time-to-market. PVcase’s Capacity Iteration feature, for instance, lets users test various parameters simultaneously, helping them identify the most efficient design faster

2. Better use of resources

PVcase’s automated layout and optimization tools allow developers to maximize energy output while minimizing structural costs.

For instance, PVcase Ground Mount includes terrain-following tracker placement features, optimizing energy production and cost efficiency by minimizing the need for extensive ground grading and structural materials.

Additionally, PVcase’s cable design feature incorporates voltage drop calculations for DC, AC, and HV cables, further assisting developers in making cost-effective decisions regarding cabling routes and component placement on-site.

3. Project scalability

Automated design tools enable developers to manage multiple large-scale projects without expanding staff proportionally. For instance, PVcase operates within the Autodesk environment, allowing users to work on several projects concurrently, facilitating smoother workflow management.

4. Improved ROI

Solar designers can use the best layout of a hundred iterations, and perform yield analysis, ultimately getting the data they need to evaluate potential returns and making informed decisions to maximize project profitability.

“I estimate that we save more than 50% of the time when generating or developing a project in its initial phase. While the difference for small plants may be smaller than manual methods, for very large plants, PVcase is indispensable. We can create multiple layouts of the same plant in a single day, a feat not possible with other software.” David Velasco, Industrial Engineer at Iberica Solar

Adoption of the automated solar design software

Using a new solution can be challenging, but with PVcase products, the transition will be smooth and user-friendly. Designed with your experience in mind, our solar software solutions are easy to navigate, requiring only familiarity with Autodesk AutoCAD to get the best out of PVcase Ground Mount.

When you adopt automated design software like PVcase Ground Mount, you'll benefit from a wealth of support. In-app guides, tutorials, and comprehensive training through the online PVcase Academy will ease your transition. Most importantly, our skilled engineers offer personalized training and assistance in your development processes completely free of charge to get you started in no time.

Conclusion

Automated solar software design is the key to an efficient, accurate, risk-free, and scalable solar project development process. With tools like PVcase, solar developers and engineers can streamline their workflow from site selection to design and yield estimation while eliminating the need to switch between tools to develop the most efficient and competitive projects.

Get a personalized PVcase demo and find out how you can be among users who reduced 50% of development time with an automated solar design software 👇

See it for yourself

Turn complexity into clarity and confidently move your data center project forward

![[EN]TOFU-navigating-site-selection-and-PV-design-trends-to-maximize-ROI-1200x518](https://hubspot-no-cache-eu1-prod.s3.amazonaws.com/cta/default/25919534/interactive-326257347792.png)

![[EN]TOFU-turning-autocad-into-a-30%-more-efficient-solar-design-powerhouse-1200x518](https://hubspot-no-cache-eu1-prod.s3.amazonaws.com/cta/default/25919534/interactive-320166276291.png)