Unlocking project profitability: how PVcase Yield ensures accurate energy production estimates

The profitability of solar projects hinges on reliable energy yield predictions. In the competitive world of solar development, even slight inaccuracies in these predictions can have significant financial consequences.

Hence, precision in energy yield modeling is not just an advantage but a necessity. PVcase Yield was developed precisely with that in mind: It provides the accuracy and confidence required for an accurate energy yield assessment and, ultimately, successful solar ventures.

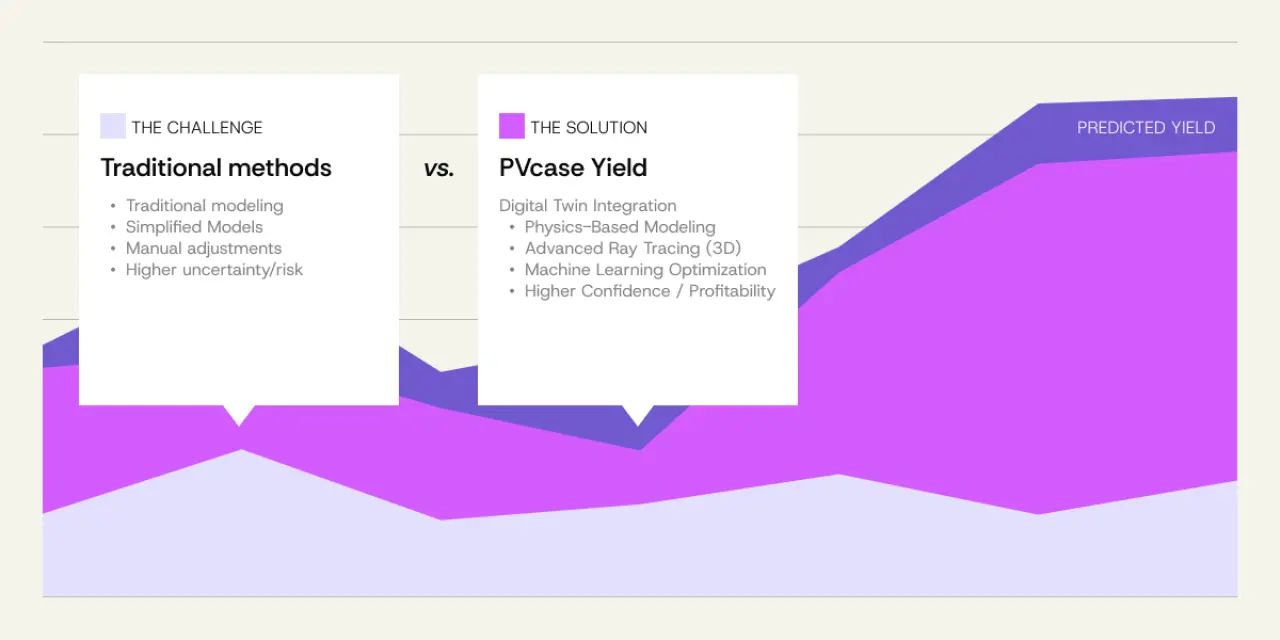

The profitability challenge: why accurate energy yield matters

Current methods for modeling photovoltaic (PV) plants often oversimplify the complex realities of solar farm performance. This can lead to inaccurate energy yield predictions, especially for advanced systems like bifacial modules and single-axis trackers on uneven terrain.

A significant issue also arises from the reliance on manual adjustments and "tweakable" parameters. This introduces the possibility of human error and makes it difficult to reproduce simulation results.

The result?

Missed financial targets and increased risk for your valuable solar assets. Furthermore, without a clear and verifiable method for predicting solar energy output, securing financing and accurately forecasting returns becomes a much greater challenge. This highlights the importance of solar yield calculation.

How precision drives project profitability: introducing PVcase Yield

PVcase Yield's advanced features are engineered to deliver the precision needed for confident investment and optimized returns.

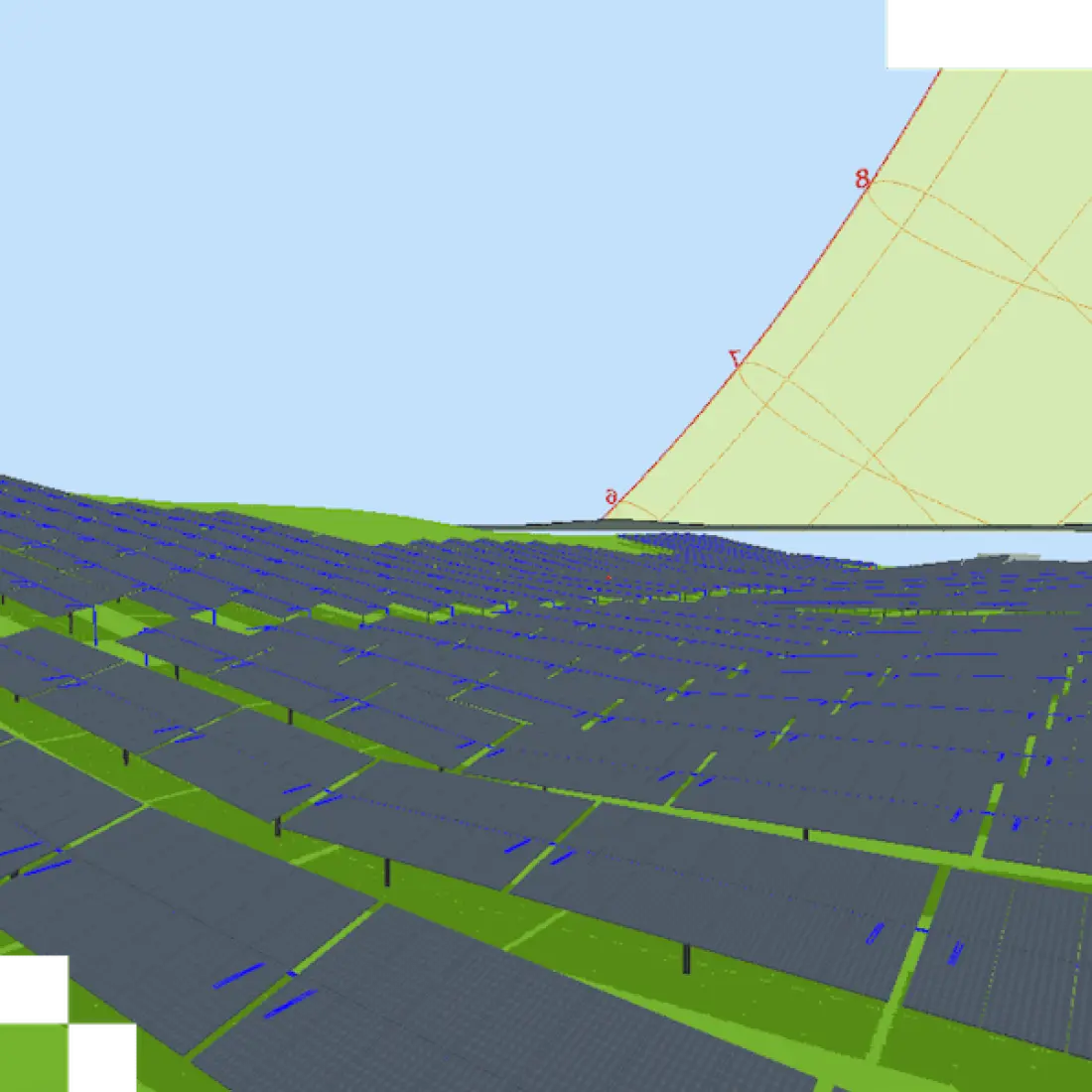

Project setting in a virtual environment: the digital twin technology

PVcase Yield addresses the shortcomings of conventional methods by directly integrating with detailed PV asset digital twins. A digital twin is a virtual representation of a physical asset that contains all the necessary information to simulate its behavior and performance.

By utilizing this digital twin technology, PVcase Yield streamlines the simulation process, minimizes manual input, and significantly reduces the risk of errors.

For instance, it allows for seamless imports of data from design files, including 3D models, topography, electrical design, and component characteristics. This removes the need for manual data entry and ensures the simulation model accurately reflects the real-world PV plant. Such foundational accuracy is the first step toward strong financial projections and a precise energy yield assessment.

Physics-based modeling

PVcase Yield also employs a "grey-box" approach using physics-based models. This means the software doesn't need to be "tweaked" for new scenarios, reducing human error and boosting confidence in results.

On the contrary, it accounts for a broad range of physical phenomena to accurately simulate PV plant performance. This includes calculating incident irradiance on both the front and back sides of modules, considering partial shading and ground-reflected irradiance. The models also capture non-stationary and non-uniform effects by running simulations at fine temporal and spatial resolutions, ensuring more accurate energy production estimates.

Integrated electrical-optical-thermal model

PVcase Yield runs simulations at fine temporal and spatial resolutions to capture non-stationary and non-uniform effects, providing a more realistic representation of PV plant performance. A comprehensive model accounts for the interplay between electrical, optical, and thermal factors. The thermal model, for instance, specifically considers heat transfer mechanisms like conduction, convection, and radiation, which depend on:

Module type

Materials

Installation geometry

PV plant layout

Irradiance

Ambient temperature

Relative humidity

Wind speed and direction

It also connects the thermal system with the solar cell's electrical model, as heat input is determined by the electrical operating point of the device. Moreover, the electrical model accounts for networks of interconnected, mismatched components, such as solar cells, bypass diodes, and strings, to accurately determine mismatch losses.

How does this benefit a solar project?

It eliminates the need for prior experimental calibration and removes reliance on subjective factors or numerous manual steps that are often disconnected from the plant's measurable physical attributes. This increases the transparency of the simulation software and reduces dependence on prior data and experience.

Ultimately, it bridges the gap between your virtually designed PV system and its estimated energy yield value, a process that is often tedious with traditional methods.

Furthermore, the inverter model has been enhanced for temperature derating, which is crucial for accurately accounting for inverter performance at high temperatures. This directly impacts project profitability by preventing the underestimation of inverter losses in warm climates and ensuring the accuracy of your revenue projections.

Advanced ray tracing

2D view factor-based models often simplify the geometry, assuming that irradiance and PV performance do not vary along the length of the rows. Such a reduction in dimensionality inevitably requires simplifications and may not accurately capture effects such as higher gain at row edges in bifacial systems, uneven topography, or the impact of shading objects.

Traditional methods may also struggle with complex terrain and often rely on user-entered parameters and simplifying assumptions, particularly for light propagation to the back side of bifacial modules.

By contrast, PVcase Yield preserves 3D layout information and simulates the PV plant as designed, without reducing it to a 2D representation. Ray tracing follows individual light rays between the sky and the solar cell surfaces, taking interactions with the detailed 3D scene into account.

PVcase Yield's 3D ray tracing explicitly computes light propagation around and through structures without such limits and simplifications, even accounting for partial shading and ground-reflected irradiance. Thus, PVcase Yield is able to accurately simulate how various aspects of a 3D PV plant model affect energy generation, including:

Localized shading on string illumination.

Electrical mismatch losses.

The influence of terrain-following frame placement on module orientation and row-to-row shading.

The effect of frame geometry, torque tubes, sun position, and ground albedo on bifacial performance.

This detailed approach provides an honest assessment of shading losses, ensuring that your financial models aren't based on overly optimistic assumptions for your solar energy output.

Machine learning

Traditional modeling often struggles with the slow iteration between designs and design scenarios, which can translate into delayed project timelines. PVcase Yield tackles this head-on by utilizing machine learning algorithms.

These algorithms analyze layouts and eliminate redundant calculations, resulting in up to 10 times faster computation times. This level of efficiency allows for the rapid simulation of even large utility-scale PV plants without compromising accuracy, directly translating to the ability for more rapid iteration of designs, conducting more sensitivity analyses, and modeling larger, more complex sites within a practical timeframe.

Consequently, developers can iterate through more design scenarios, quickly identify the most efficient layouts, and optimize the DC/AC ratio for peak financial returns.

Probabilistic estimates

P75, P90, or P95 energy estimates are crucial for financial modeling and risk assessment in solar projects. They provide a range of likely outcomes for energy yield and help developers, investors, and operators make more informed decisions about project viability and financial returns.

For example, a P90 estimate means there is a 90% probability that the actual annual energy production of a solar power plant will meet or exceed the estimated P90 value.

PVcase Yield can now calculate P75, P90, or P95 energy estimates, providing comprehensive risk assessments and projections to stakeholders to help secure financing and ultimately assure project viability.

Validation and benchmarking: proving accuracy and reliability

Given the criticality of precise energy yield assessment for solar projects, tangible proof of accuracy is essential. PVcase Yield's accuracy has been rigorously validated:

Real-world data verification

PVcase Yield has undergone rigorous validation against real-world data from various sources. These include:

A large utility-scale PV plant in Spain (with an nMBE of -0.5% and nRMSE of 9.2% at 15-minute resolution).

An outdoor lab-scale installation in Italy (with an nMBE of 1.13% and nRMSE of 3.27% at 1-hour resolution).

Datasets from Denmark Technical University (DTU) and National Renewable Energy Laboratory (NREL).

These studies demonstrate close matches in irradiance and temperature simulations and confirm PVcase Yield's ability to predict energy yield across diverse PV systems and conditions accurately.

Benchmarking against industry standards

An external Black & Veatch study compared PVcase Yield with PVsyst, an established industry-standard software. The study found comparable performance between the two software packages.

Differences in energy injected into the grid for the first year ranged from 0.24% to 2.4%. Consistent differences were observed in specific loss terms, such as front-side transposition gain, front-side near shading, IAM losses, low light losses, and transformer losses.

Collaboration with Imec

PVcase Yield was co-developed with Imec, a world-leading research and innovation hub in nanoelectronics, leveraging their extensive R&D expertise in physics-based PV energy yield simulation. This collaboration ensures that PVcase Yield is built on a solid foundation of scientific knowledge and benefits from the latest advancements in PV modeling technology.

The solution for high precision solar energy prediction

Securing high project profitability in solar development demands an absolute commitment to accuracy. The limitations of traditional energy simulation methods, particularly their tendency to oversimplify PV plant performance, frequently lead to financial shortfalls and increased risk.

PVcase Yield represents a shift in this regard: By seamlessly integrating with digital twins, utilizing physics-based models, and leveraging advanced ray tracing and machine learning techniques, it provides solar engineers and developers with the tools they need to make informed decisions and maximize the potential of their solar assets.

PVcase Yield product guide

Download the product guide to:

Improve your design's accuracy.

Gain greater layout flexibility.

Boost your project's transparency.