Every solar farm project starts with clear goals: location, capacity, and expected returns. A feasibility study evaluates solar irradiance, terrain, grid proximity, and environmental factors — all essential for long-term success. This stage sets the foundation for accurate solar park design and site suitability.

The basics of building a solar farm at scale

Building a solar farm is a multi-step process that requires precision, planning, and in-depth technical expertise.

From land evaluation to solar power system design and performance modeling, each stage presents its own risks, and many solar power plant projects fail before reaching the construction phase.

This guide breaks down the fundamentals of solar farm design, explaining how utility-scale solar development works in practice. Whether you're exploring how to construct a solar power plant or optimizing an existing workflow, PVcase’s integrated platform helps solar projects move from idea to execution faster, with greater confidence and fewer setbacks.

How to design a utility-scale solar farm

Designing a solar power plant involves multiple stages — each with its own set of data requirements, technical risks, and decision-making complexity. For projects built on uneven or suboptimal terrain, the stakes are even higher. Let’s now unpack the basic stages of the solar power system design process.

1. Conducting a feasibility study

Before a single panel is placed, every utility-scale solar project begins with a feasibility study. This phase determines whether a solar power plant is viable based on several key points:

Land availability and ownership constraints

Solar resource potential

Grid connection feasability

Environmental impact and protected zones

Environmental impact assessment

One of the most important points is that solar farms must coexist with their environment. An early and thorough environmental review reduces risk and builds community trust. Typical focus areas are:

Wildlife protection and habitat preservation

Glare analysis near roads or residences

Mitigation of erosion, runoff, or dust

Project economics

Another important step is doing a financial analysis to evaluate the economic viability of the solar plant. If a solar farm isn’t financially viable, it won’t be built. Economic modeling runs parallel to every stage of development. Points of consideration are capital costs, operational expenses, revenue generation, incentives, and return on investment.

2. Determining the system size based on the feasibility study

Once the solar project’s viability is determined, developers decide on the system size based on energy targets and project goals.

It allows for quick iterations based on module type, frame configuration, and tracking system. This way, it helps engineers test multiple layout sizes early without manual recalculations.

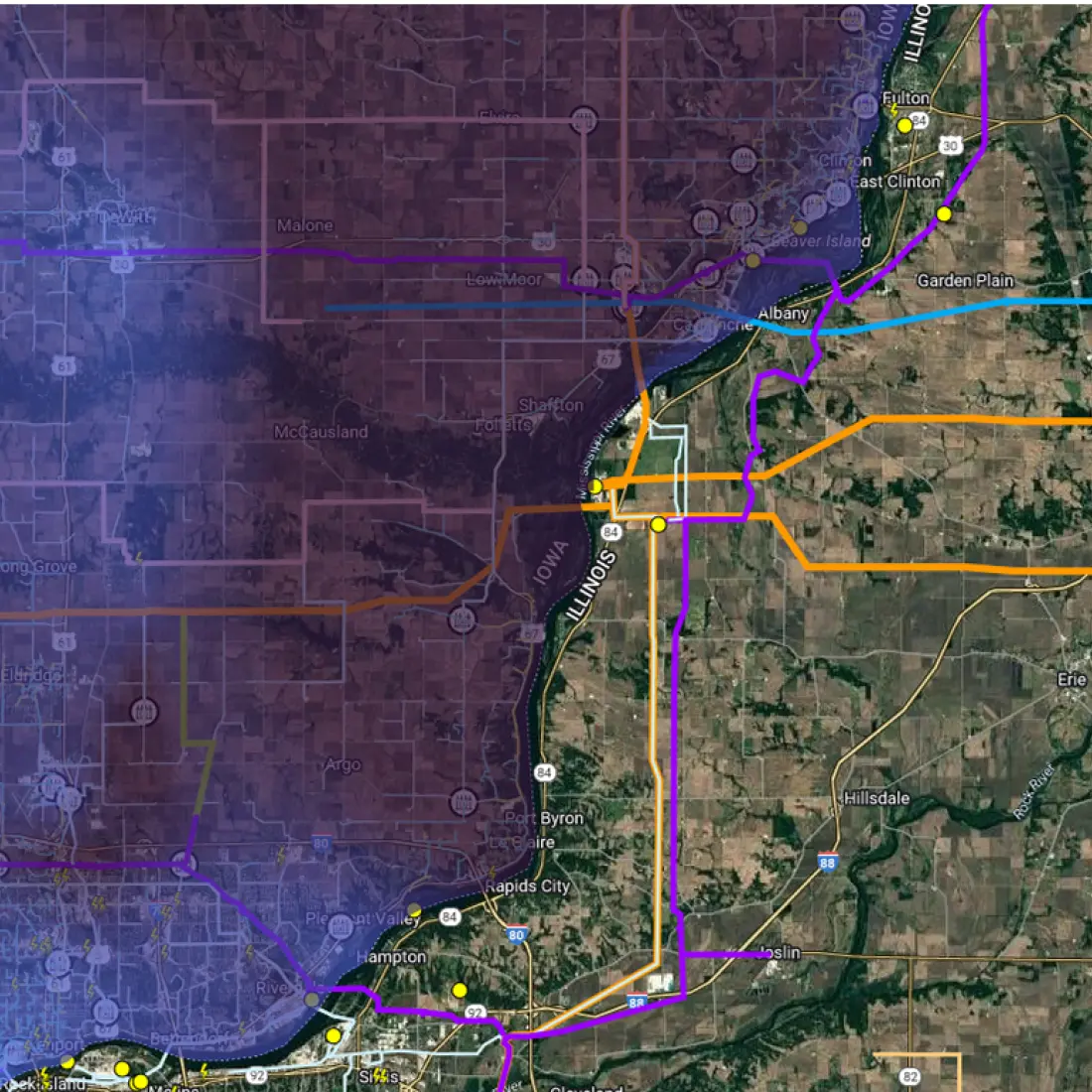

3. Selecting a site

Site selection is more than just identifying sunny locations. It involves navigating multiple constraints while preserving buildable acreage:

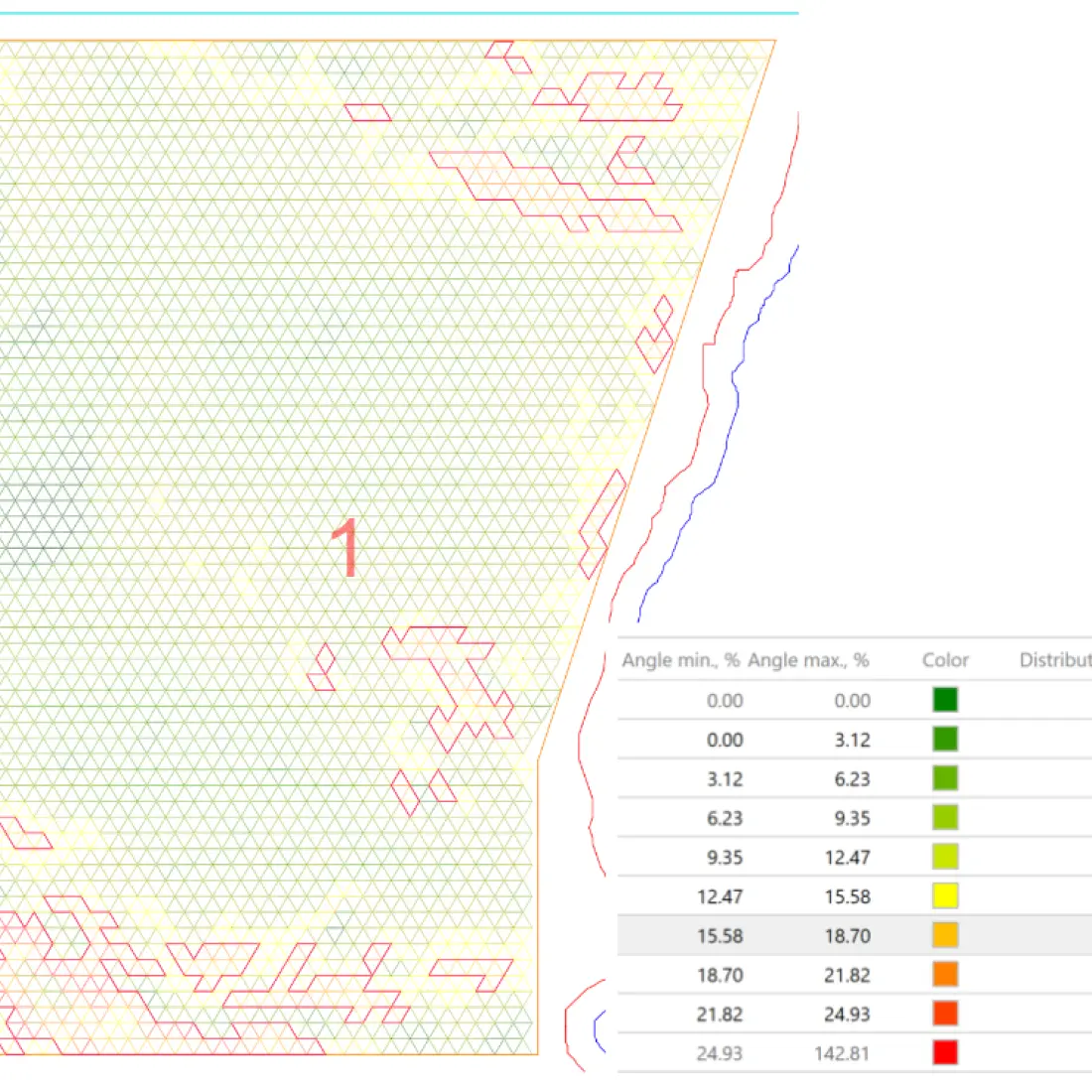

Topography and slope risk

Access roads and transmission line proximity

Avoidance of protected habitats or flood zones

Parcel size and configuration

Interconnection and grid integration

When delving into renewable energy project site selection, the strategic evaluation of optimal interconnection points takes center stage. These points, often called POIs, encompass substations, transmission lines, and distribution grid feeder lines.

Their proximity plays a pivotal role not only in streamlining grid integration but also in shaping the financial landscape of the venture. While shorter distances to POIs generally translate to reduced transmission and distribution costs, there are not many parcels near ideal POIs with sufficient capacity for the project; this makes the calculus more intricate when considering locations farther from your ideal POI.

By conducting thorough analyses of the transmission infrastructure, renewable developers can identify substations and transmission lines with sufficient capacity to accommodate their projects before conducting traditionally expensive and time-consuming site analysis.

4. Performing a solar resource assessment

Once a site is shortlisted, the next step is understanding how much sunlight it will realistically receive. This involves:

Analyzing long-term solar radiation data

Performing shading analysis based on terrain and vegetation

Evaluating the impact of slopes and azimuth on irradiance

5. Choosing the solar technology

Choosing the right solar technology is also a fundamental step. It impacts not just energy yield but also installation complexity and long-term performance. At this stage, developers decide between photovoltaic (PV) or concentrated solar power (CSP), and within PV, select specific configurations like:

Fixed-tilt systems: simple to install and maintain, ideal for flat or lightly sloped sites, but can limit overall yield.

Single-axis trackers: boost energy production by following the sun, but require slope uniformity and add structural considerations.

Bifacial modules: capture light from both sides, increasing output, but depend heavily on ground reflectivity and tilt optimization.

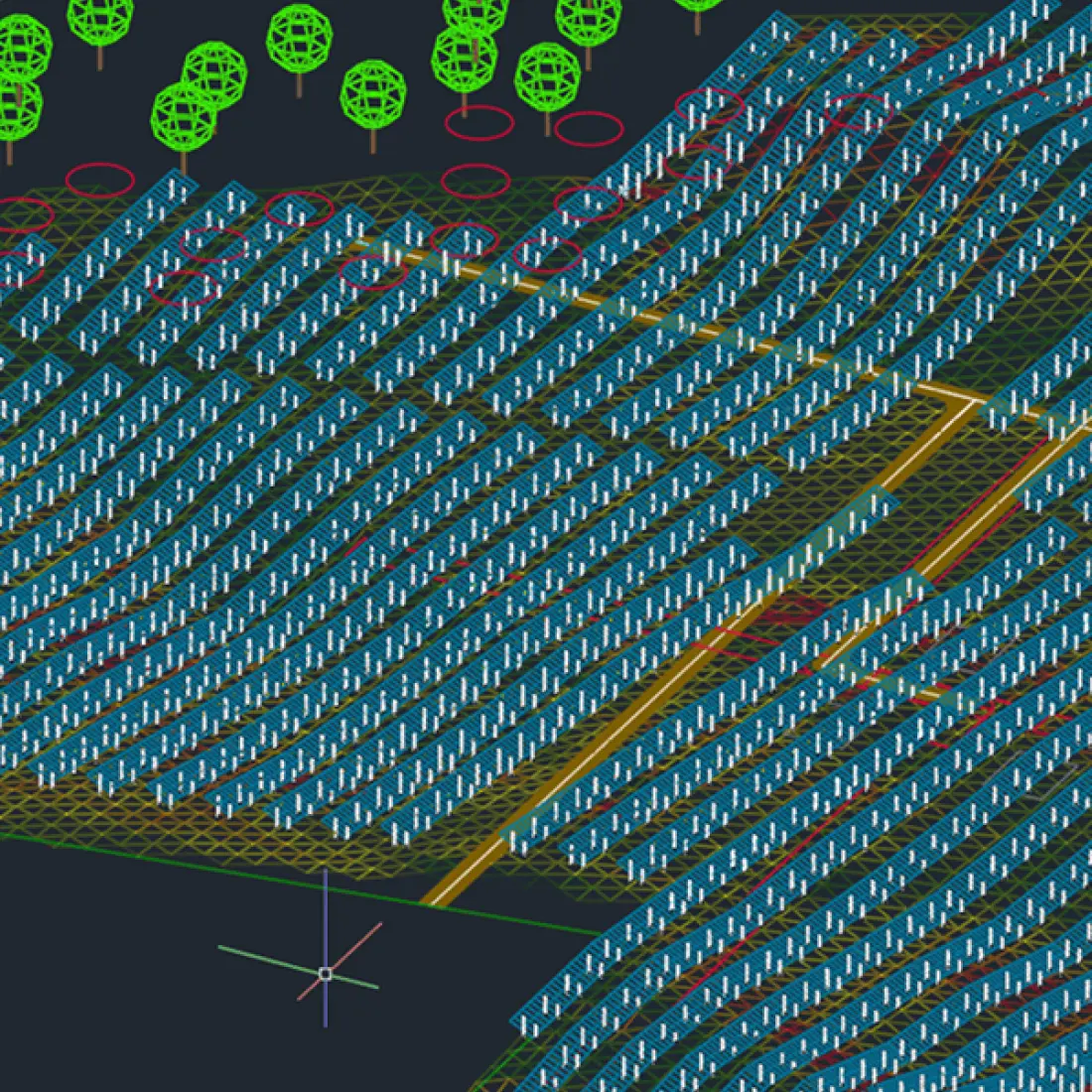

6. Making a solar plant layout and design plan

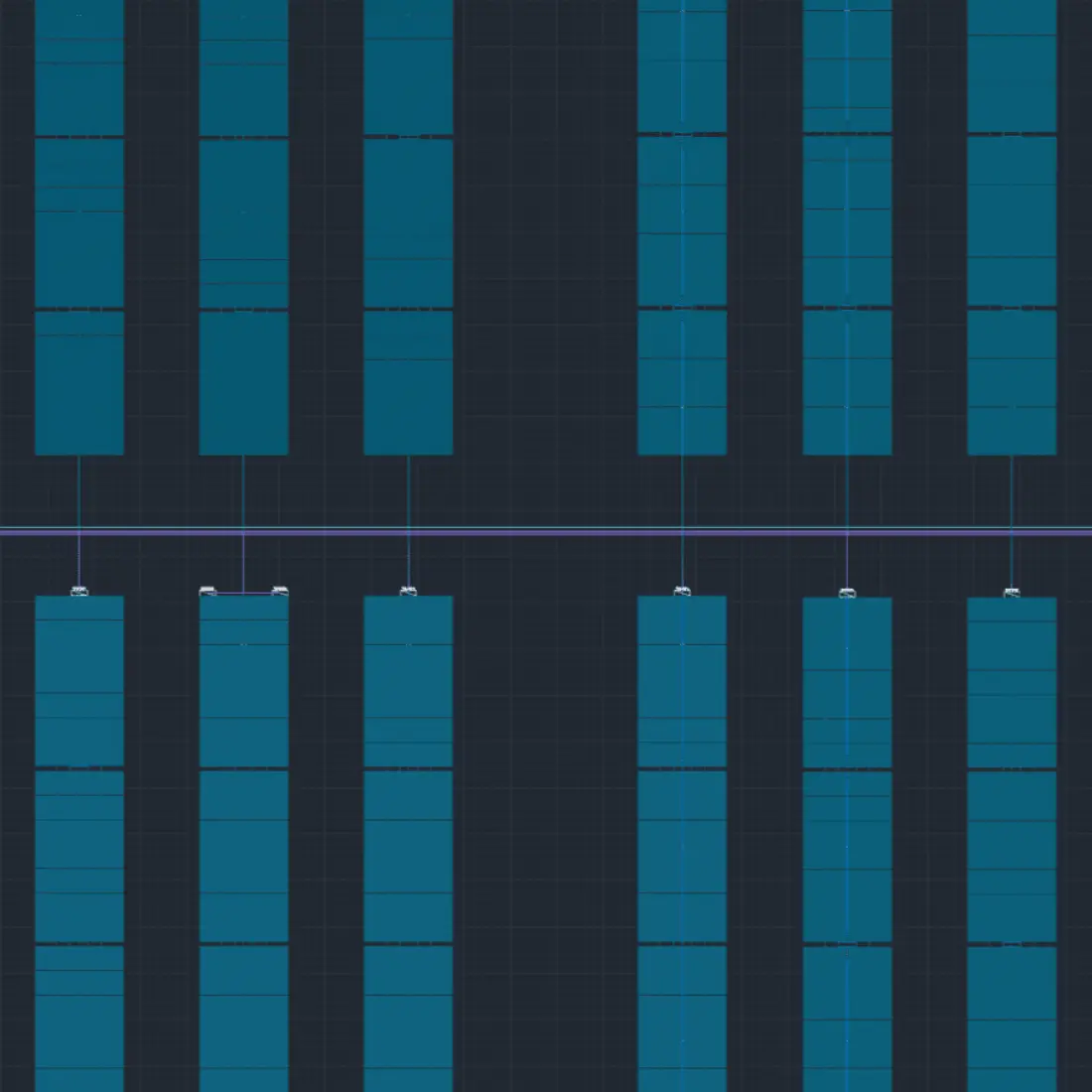

The layout is where solar potential meets real-world constraints. It defines how efficiently a site can convert sunlight into electricity and how costly it will be to build.

At this stage, engineers define the optimal tilt and orientation of solar panels, row spacing to avoid self-shading and improve airflow, land usage strategy — balancing density, terrain, and constructability, and how to reduce grading and adapt to slopes or irregularities.

7. Civil and structural design

Designs on paper must withstand real-world forces. This step guarantees the solar power plant is structurally sound and constructable.

It includes practical considerations — such as limiting slopes to what the construction equipment can handle and avoiding potential collisions between frames and the terrain. Drainage, access roads, and construction logistics are also mapped out at this stage.

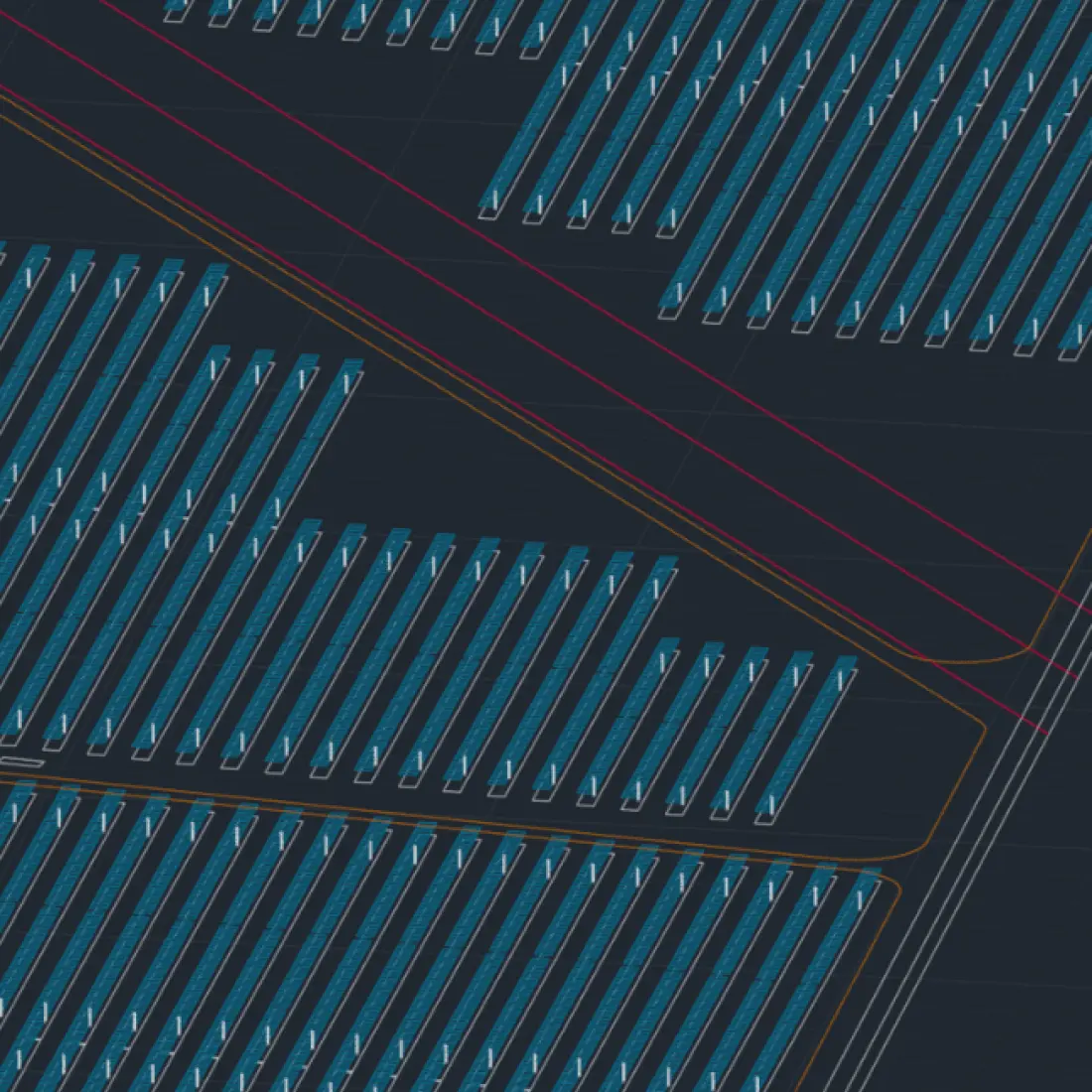

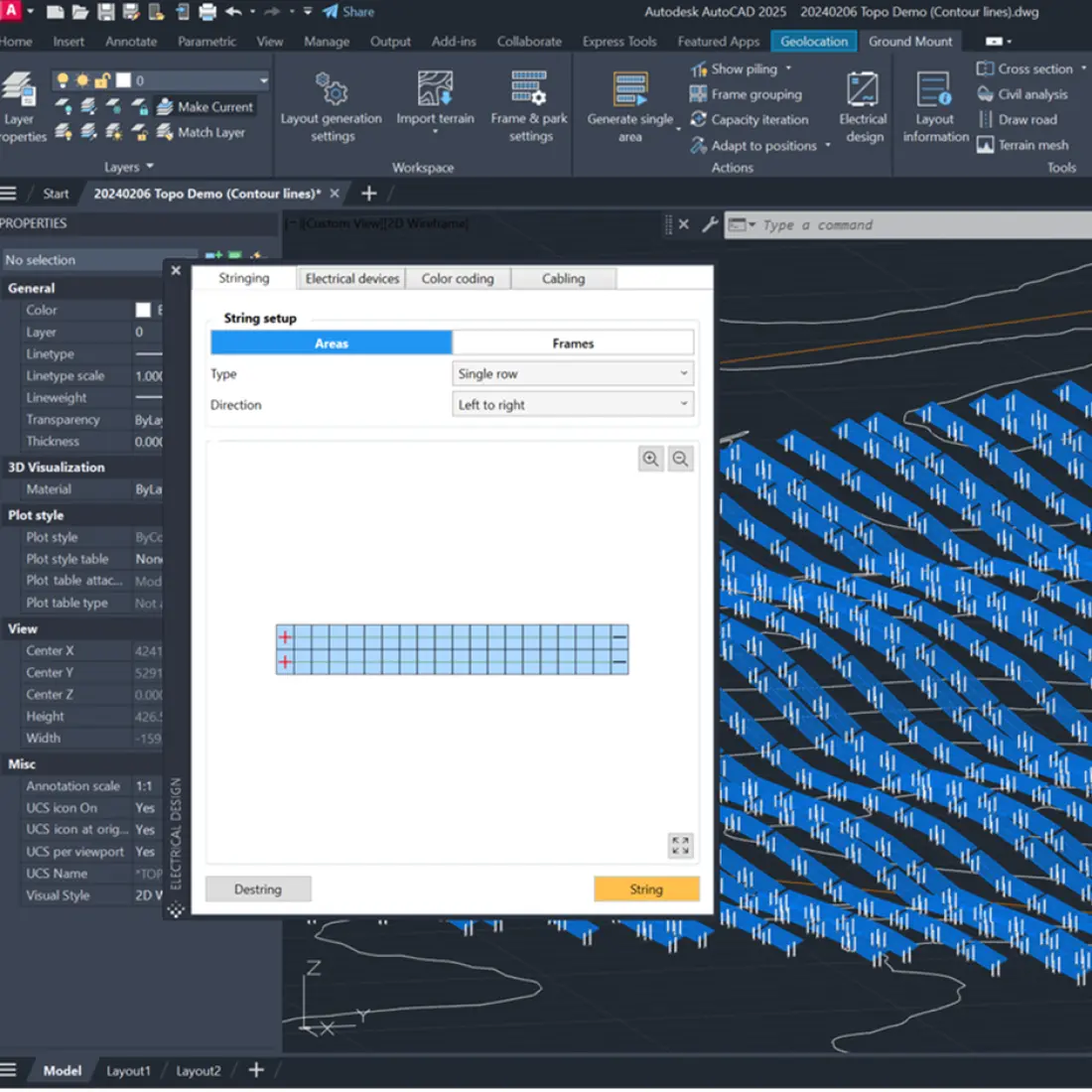

8. Creating an electrical design

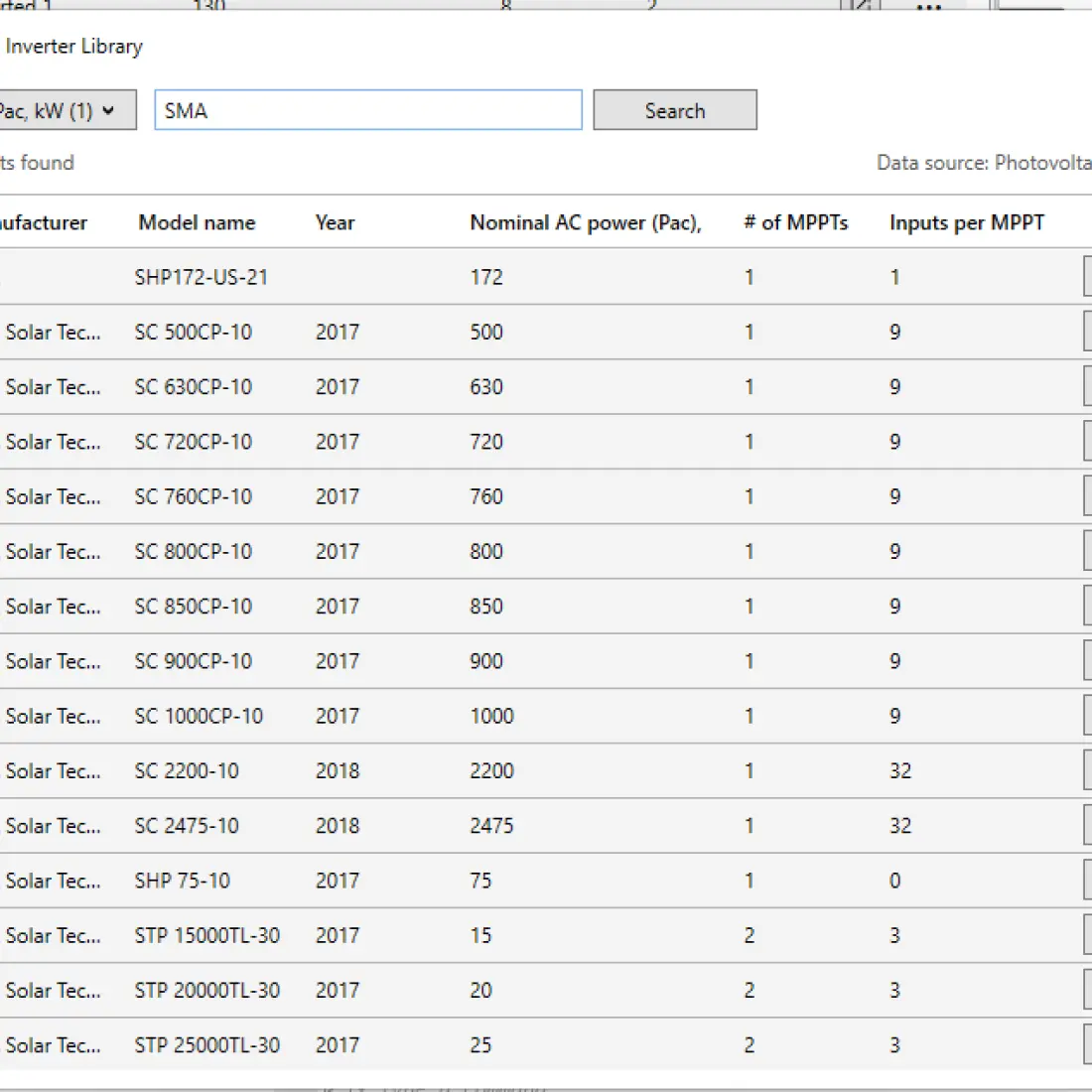

After the mechanical layout is finalized, attention turns to how energy will flow across the solar farm. The electrical design connects all components: the configuration of solar panels, wiring, solar cabling, inverters, transformers, and more.

Before even beginning the electrical design, engineers should have a clear understanding of the equipment they plan to use, including inverters, transformers, and other electrical components.

It's crucial to know the planned location of the power station and have a clear idea of where intermediate electrical devices like inverters and DC combiners will be placed. Without this prior analysis, engineers may face long cable runs, resulting in extra costs due to increased cabling and higher voltage drops, which require larger (and more expensive) cable sizes.

One of the most significant challenges in electrical design is generating realistic DC, AC, and HV cabling layouts. Errors in cabling arrangements can lead to procurement issues, construction delays, and increased costs.

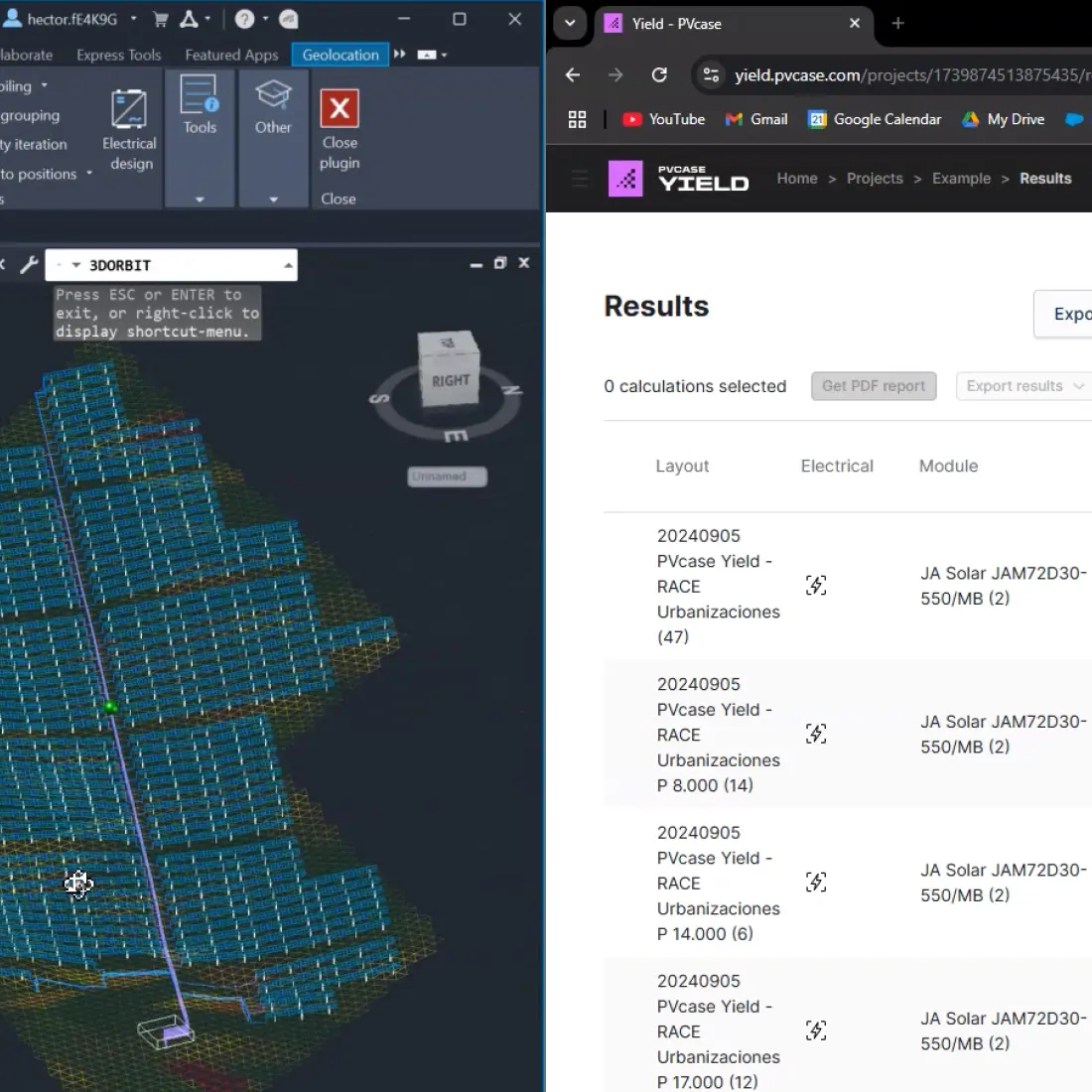

9. Estimating the energy yield of photovoltaic (PV) power plants to make informed decisions about project design

Before moving into construction, it's pivotal to estimate the solar plant’s projected energy output. This step assures that the current design delivers on performance expectations and meets financial goals.

Using advanced simulation tools, designers assess how much electricity the plant is expected to generate — factoring in shading, terrain, weather patterns, and system losses. If the calculated yield falls short of targets, the layout may need to be adjusted or re-optimized before breaking ground.

10. Construction and commissioning

Once designs, permits, and other elements are in place, the project moves into the field, ensuring adherence to the design plans and safety standards. This phase includes:

Civil works and foundation installation

PV module mounting and cabling

Final testing and commissioning

11. Maintenance, monitoring, and performance analysis

A solar farm’s success doesn’t end at commissioning — it must be maintained for decades.

The next step would be outlining a comprehensive operation and maintenance plan for the solar power plant. This includes regular inspections, cleaning of panels, equipment maintenance, performance monitoring, and troubleshooting.

On top of that, the monitoring system needs to be set up to continuously track the plant’s performance, identify potential issues early, and adjust operations to maximize energy output.

Building a utility-scale solar farm

Now that the solar PV design is in place, a new phase in the construction of the utility-scale solar power plant begins — one that requires precise coordination across engineering, procurement, permitting, and site execution. The truth is, about 80% of solar projects fail along the way. Delays and fragmented planning can stall progress indefinitely. Let’s break down the major steps that take a photovoltaic plant design from concept to commissioning — and eventually, to energy generation.

Main stages

How much does building a solar farm cost?

The cost of building a solar power plant can vary widely depending on numerous factors like the size and capacity of the plant, the location, the technology chosen, the cost of labor and materials, and any additional infrastructure requirements.

As of June 2025, a 1 MW solar power plant could cost between $800,000 and $1.5 million. However, it’s worth noting that smaller-scale projects or projects in certain regions may have higher costs due to various factors such as economies of scale, access to materials, and local labor costs.

Additionally, it’s essential to consider that the costs of solar power plants have decreased over time due to advanced technology and increased adoption.

To obtain more accurate and recent cost estimates for building a solar power plant, we recommend consulting with solar project developers, engineering firms, or industry reports that provide specific data on project costs in a chosen region. You also need to evaluate the following factors:

Size of the project and its design peculiarities

Price of the materials

Financing options that are available in a chosen country

Location costs (depends on the country). It can affect the land rent costs, the available subsidies, state policies, and more

Labor and maintenance costs (workforce costs depend on the location where the solar plant is being built)

The construction costs of a solar power plant

Hard costs

Solar panels: 12%

Inverters: 10%

Racking and mounting equipment: 3%

Wiring: 9%

Soft costs

Labor: 7%

Permitting and interconnection: 8%

Sales and marketing: 18%

Overhead: 11%

Profit: 11%

Supply chain costs

Logistics & sourcing: 9%

Source: EnergySage

The cost of a solar plant project in the US (according to EnergySage)

Solar power plant design precision with PVcase: 10 platform advantages

Designing and building a solar power plant requires expertise in various fields, including engineering, electrical systems, environmental impact assessment, and project management. Partnering with experienced solar design professionals plays a key role in keeping complex projects on track — from feasibility to final output.

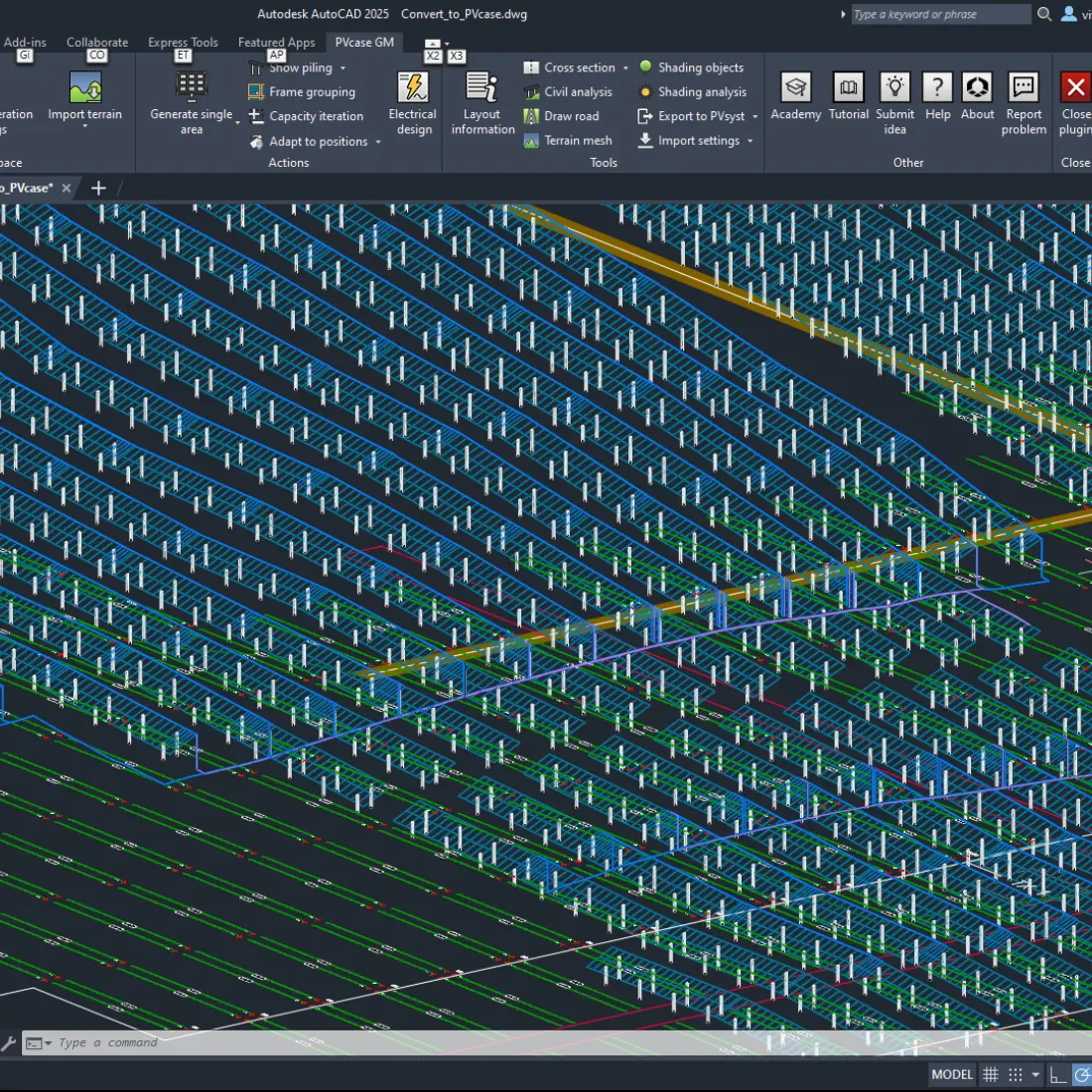

PVcase is the right choice for solar project development throughout its entire lifecycle. PVcase Prospect optimizes site selection, while PVcase Yield offers unmatched accuracy when it comes to simulating a power plant's output. When it comes to the actual design, PVcase Ground Mount stands out for their efficient process automation, which translates into more flexible, faster project development.

With automation, terrain intelligence, and integrated workflows, PVcase helps solar teams design faster, reduce risk, and unlock greater precision on complex terrain. Here are 10 key advantages that showcase how PVcase streamlines utility-scale solar design and planning:

Faster design iterations

Spend less time reworking layouts by adjusting designs instantly with terrain and equipment data in one place.

Built-in terrain intelligence

Visualize slopes, grading, and elevation changes early to avoid surprises later in construction.

Design validation as you go

Spot and resolve layout issues like clearance gaps or constructability challenges during the design phase.

Multi-area site support

Work seamlessly across irregular sites by dividing the layout into manageable zones.

Integrated civil and electrical planning

Bring together structural, electrical, and civil considerations within a single workflow.

Layout flexibility

Adjust frame positions, spacing, and orientation to maximize yield and reduce earthwork.

Real-time collaboration

Keep design teams aligned with cloud-based file sharing and up-to-date versions.

Compatibility with existing tools

PVcase is an integrated suite, so engineers can easily convert existing designs from CAD and adapt them to PVcase projects.

Fewer manual tasks

Automate cable routing, labeling, and other repetitive steps to reduce errors and save weeks.

Export-ready documentation

Generate project files, such as layout drawings and equipment lists, instantly for EPC handoff.

Conclusion

Building a solar farm is a complex, high-stakes process, and many projects never see the light of day. From site selection to performance modeling, each phase demands precision, coordination, and deep technical insight.

This guide walked through the main stages of design and development, highlighting where things often go wrong. With PVcase, developers can shift from fragmented workflows to a unified, automated suite of tools, reducing risk and accelerating results. It's solar development designed to succeed — and to see the light of day.

Try PVcase now

See our AutoCAD-based solar design software in action and learn how it can benefit your business. PVcase leverages automation, a high level of precision, and intelligent algorithms to improve the efficiency, accuracy, and quality of PV designs.