The solar industry is constantly innovating and improving, yet there are staples of any solar park that are present in every project. Understanding what to expect at the beginning of the construction and knowing how to navigate potential challenges, or how to avoid them altogether, could greatly boost the performance of the solar park, as well as reduce expenses.

What is ground grading?

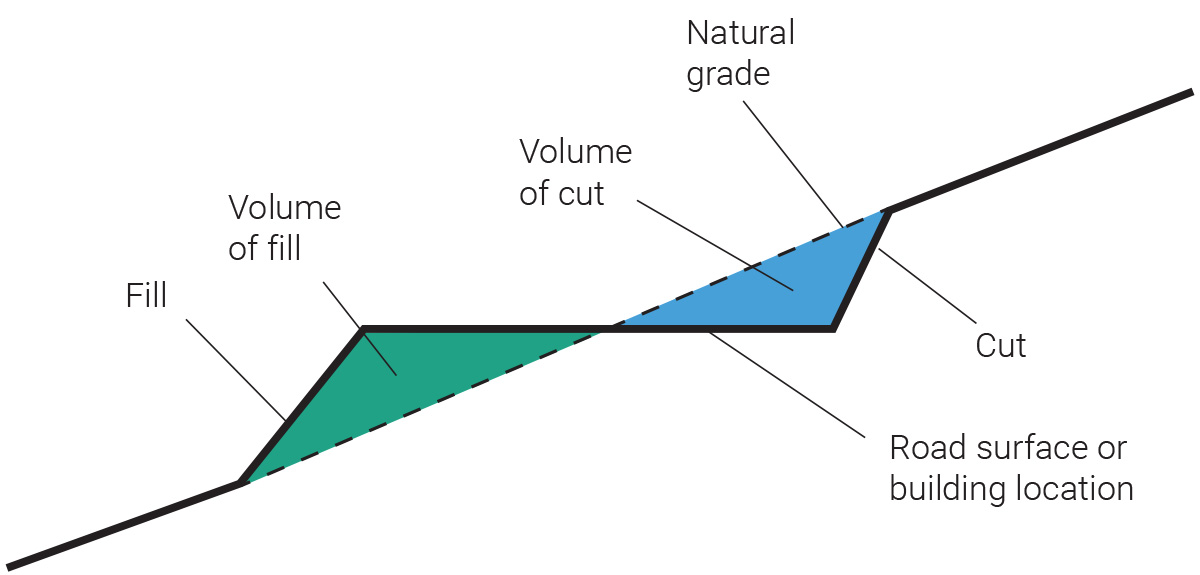

Assessment of the terrain is fundamental to any solar project. Simply put, it’s the process of checking whether earth preparations will be required at the location for the solar park. Terrain analysis can be used to evaluate uneven surfaces and similar disturbances in order to check the land assigned to a project. After that, a ground grading calculation shows how much work needs to be put into the location in order to create a flat surface and remove vegetation for easier construction.

Ground grading is not exclusive to the solar industry, and due to its widespread use, it can be known by several different terms, such as earthworks or cut-and-fill. Either of the terms describes the act of altering the surface of the land.

Essentially, ground grading is one of the most reliable means of improving the project’s viability. It provides the analysis of how much it would cost to place the equipment in suitable locations for maximum performance and provides input for the civil engineer to determine the impact that earthworks would have on the project.

Ground grading and civil design

Ground grading falls under the umbrella of civil engineering. As a broad concept, in terms of solar, civil engineering takes into account the overall planning and construction of the plant. This includes evaluating location and determining water drainage, soil suitability, and environmental impacts. Ground grading, on the other hand, focuses directly on the assessment of the PV area. In a scenario where there are plans to build a solar park in a location near cliffs, the civil design could evaluate the environmental impact the project might have and create a design for the park. Ground grading is then needed to prepare the location for construction, including moving the earth around to create a flat surface or removing obstacles such as trees.

The combination of both is needed to successfully determine the location of a solar park. Additionally, ground grading requires oversight from civil design to ensure the project’s costs won’t rise too much; the intricate relationships between the two also keep the maintenance of the project manageable. In worst-case scenarios, a lack of understanding or preparation for ground grading or civil design could result in exponential losses.

Ground grading costs

The cost of ground grading consists of several elements. The first one is the expense of preparing the surface for a solar park. This can be anything from cut-and-fill operations of displacing ground to removing bumps and placing it somewhere else to fill out the dips; it can also include the removal of boulders, trees, and similar obstacles. Ground grading can become an expensive endeavor, especially in more remote locations, since the ground work includes both transportation and labor costs. Additionally, civil design can point out any major problems with the land, such as stony conditions or water drainage issues.

The second element of the overall cost is maintenance. This is more applicable when the project requires modifications to the land. Let’s say the park is being built on uneven ground and in order to flatten the surface, modifications to the land were done, including shifting some of the ground around. This can cause instability, and in certain situations, this can lead to landslides or similar displacements, which can damage the park and require additional investments to keep the project operational.

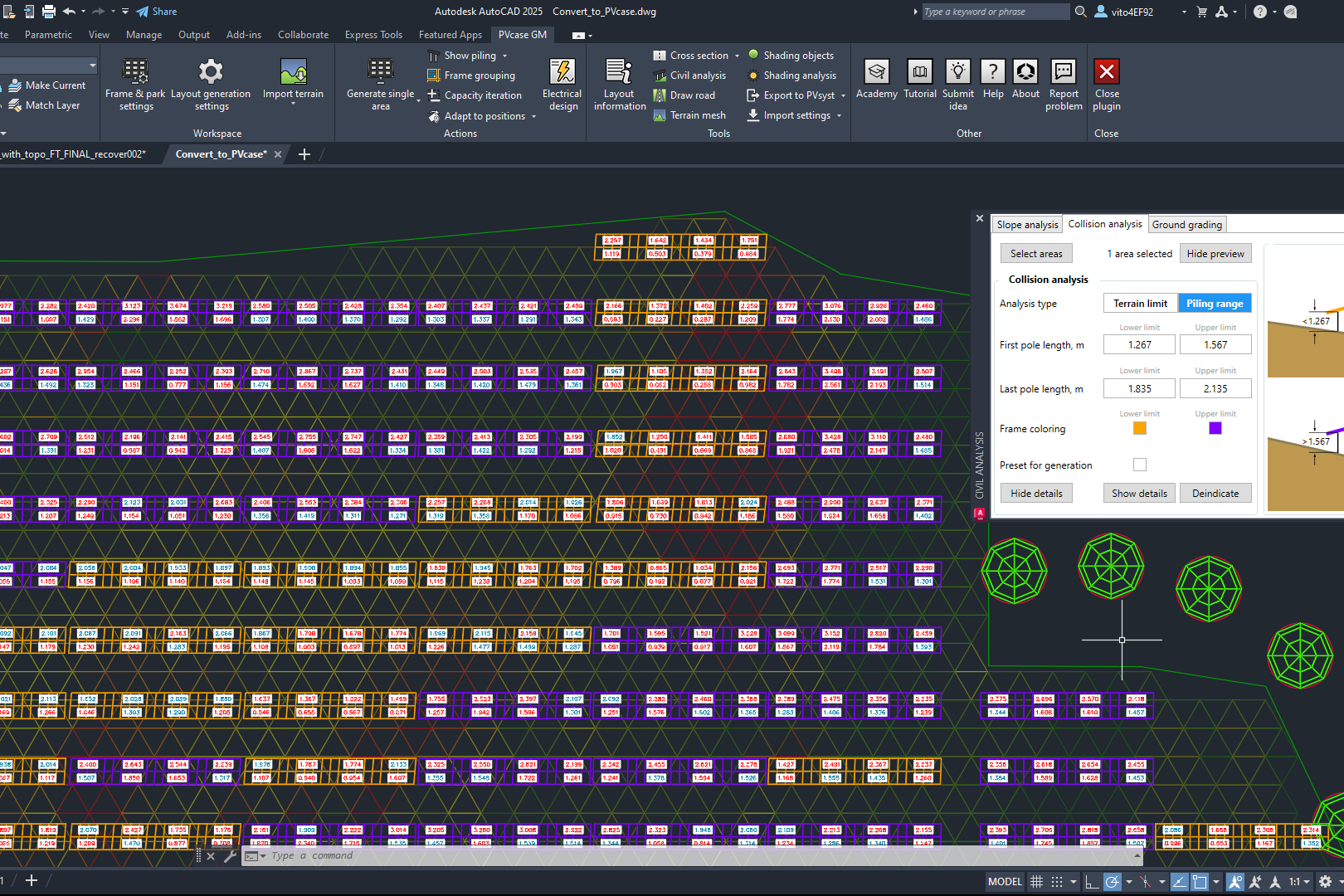

Minimizing ground grading expenses with PVcase Ground Mount

Fortunately, there are ways to offset the ground grading costs without sacrificing the efficiency of the project. PVcase Ground Mount helps resolve collision and slope issues of the project, visually reflecting the data on the plan so that engineers can accurately determine the pole length range and slope limit according to your data and the specifics of the PV framework. Additionally, the cut and fill calculation will show the value of the number of earthworks required. It allows the engineers to predict the viability of a project, as well as determine the potential costs. The ground grading feature ensures the solar project has all the information regarding the earthworks and the attached expenses.

You might also be interested in:

July 19, 2024

Siting of PV power plants. How to adapt solar designs to complex terrains?

Choosing the wrong PV project site lowers energy output, raises costs, and risks legal issues. PVcase offers solutions. Discover them by reading the article.

July 16, 2024

Overcoming technical challenges in renewable energy projects. How PVcase transformed OHLA’s design process

Explore how OHLA overcame renewable energy design challenges with PVcase, streamlining solar park operations and achieving remarkable business growth.

July 3, 2024

Bridging the renewable energy skills gap. A success story of PVcase, Enery, and the University of Applied Sciences Upper Austria

Discover how PVcase, Enery, and the University of Applied Sciences Upper Austria have collaborated to prepare future solar engineers through an innovative educational initiative,…

July 1, 2024

Top 10 questions from Intersolar Europe 2024, answered

Get answers to the top 10 questions asked during Intersolar Europe 2024 that cover PVcase Prospect's availability, integration of PVcase products, and much more. Your question is…

June 19, 2024

Targeted solar marketing for successful landowner outreach — e-book included!

Discover how innovative strategies and Anderson Optimization's GIS Site Selection can boost solar outreach ROI and conversions. Download the ebook for more insights!

June 3, 2024

PVcase is part of the 42-month long SUPERNOVA project

PVcase, together with 19 partners from all over the world, is part of the 42-month SUPERNOVA project, focusing on O&M and grid-friendly solutions for reliable, bankable, and…

May 29, 2024

PVcase tools are now compatible with AutoCAD 2025!

We’re happy to announce that you can now use PVcase Ground Mound and Roof Mount, our flagship CAD-based tools, on AutoCAD 2025, enjoy its multiple functionalities and integrate…

May 20, 2024

PVcase is the finalist of “The smarter E AWARD” in the Photovoltaics category

We’re the finalists of “The Smarter E AWARD”! Read more about the nomination and dive into the PVcase Integrated Product Suite offering that innovates the industry.

May 14, 2024

Making great designs on good sites—the importance of topo data for PV design

Topo data is the first step in determining the success of your solar project. While the terrain is crucial in this regard, developers should also consider grid connectivity and…

April 29, 2024

How policy can shape future solar energy expansion

Policymakers and regulatory organizations must actively support solar power's growth and renewable energy advancement. Read the article to learn how.

April 25, 2024

Shading Analysis: advanced feature for C&I roof-mount solar projects is live

Shading Analysis is live! Read the article to learn about benefits, capabilities of the tool, and how it can help users and decision-makers.

April 9, 2024

PVcase wins the BNEF Pioneer Award 2024 for innovative solar design solutions

We won the prestigious 2024 BNEF Pioneers Award! Find out how our software contributes to relieving bottlenecks in the deployment of clean power.

March 29, 2024

Sustainable cities: what urban living of the future might look like

From clean energy to green bonds and renewable energy stocks, there are many ways you can invest your money in a sustainable future. Find them out by reading the article.

March 22, 2024

8 ways to invest your money in a sustainable future

From clean energy to green bonds and renewable energy stocks, there are many ways you can invest your money in a sustainable future. Find them out by reading the article.

March 21, 2024

8 business opportunities in renewable energy

There are many potentially lucrative business opportunities in renewable energy. Learn how you can use these opportunities to make money while contributing to the green…